Advice: Right-hand-drive Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

Advice: RHD Conversions

|

|

Advice: RHD Conversions

|

|

|

Advice: RHD Conversions

|

|

|

Advice: RHD Conversions

|

|

|

Advice: RHD Conversions

|

|

|

Advice: RHD Conversions

|

|

|

Advice: RHD Conversions

|

|

|

Advice: RHD Conversions

|

|

|

Advice: RHD Conversions

|

|

|

Advice: RHD Conversions

|

|

|

Advice: RHD Conversions

|

Want that modern American muscle car? Then follow our tips for a legal, quality RHD conversion

RHD CONVERSIONS

It would be so much easier if we could all drive on the correct side of the road, which is obviously the left side. Of course the Americans suggest that the right side is the right side, and if two wrongs don’t make a right, what do two rights make? It’s all very confusing but the fact is, driving on the right side is mandated for about 90 per cent of the total length of the world’s roads. Clearly, Australia is likely to have a healthy, viable vehicle conversion industry for a long time to come.

So, how do you convert a car from left-hand drive to right-hand drive? Start young, if the experiences of Craig Dean and Albert Paternoster are anything to go by. Craig says he started doing Camaros in his back yard back in the early 1980s before he joining the Air Force, where he trained as a mechanic officially. When he got out in the late eighties he met Alby, who was already in the conversion business and the pair pooled their talents. Crossover Car Conversions is the result.

These days Crossover specialises in newer muscle cars. Specifically, Mustangs, Camaros, Corvettes, Challengers, Ford GTs, F-series trucks (including Raptors), basically post-’89 vehicles listed under the SEVS Scheme. As a RAWS facility Crossover can also do the work needed to get an unlisted vehicle included on the SEVS register.

Almost everything is interrelated, so the first step is to strip out everything that has to be modified, or which prevents access to whatever needs to be modified. For instance, the engine doesn’t have to be changed but it stands in the way of firewall alterations, so out it comes. The firewall is central to steering, brake, clutch, dash and climate control systems, so it has to be altered before anything can be fitted. Some cars are harder than others but the general principle is to alter as little factory metal as possible. Craig suggests that Camaros are one of the easier cars because the firewall is fairly flat and it’s easier to fit plates. Mustangs, on the other hand, have a lot of shape in the firewall so it’s more difficult to make accurate replacement sections.

It takes a fair amount of time and experimentation to work out the best way of modifying the firewall and other components. Rather than working it out (and measuring it) each time, Crossover uses templates to guide the cutting operations. Commonly used replacement sections are laser-cut for convenience and accuracy. These, along with the custom-formed sections, are set in place, welded and painted. Firewall modifications to the Mustang (as used in these images) included the fabrication of a heater box extension and alterations in the wiper channel. Attention to sealing is extremely important in the firewall area because of the potential for leaks, from both rain and the climate control or air-conditioning system.

The windscreen wiper motor is mounted in the same position but the extension to the driver’s side wiper (in US configuration) is cut off, mounted in front of the Australian driver and joined to the motor assembly by an extension bar. Two other levers are turned in the opposite direction and the finished job meets the relevant ADR. It must be said that there are some inconsistencies in the regulations relating to imports and the windscreens highlight this. In a used import, light transmittance must be 75 per cent. A new low-volume import only has to transmit 70 per cent. Go figure.

OFF THE RACK

Once the firewall is prepared, moving the steering wheel and column to the right is but a small part of getting the wheels pointed in the right direction. First, the column and linkages have to pass freely between any obstacles such as exhaust headers and the side of the engine bay. Then, of course, the rack has to be replaced with an externally compatible unit that fits. Craig says the racks are also modified internally to achieve appropriate operating characteristics. On some cars, such as the Ford F150 Raptor shown, the factory rack can be reversed if appropriate modifications are made.

Steering is a good example of how technically challenging conversions are becoming. Current Mustangs, Corvettes, F150s and Camaros have electric steering. Crossover has retained the factory electronic motors for these systems but has had new extension housings and internal shafts engineered to mate with the factory components, in the correct orientation for right-hand drive. These extensions are a work of engineering art but they add about $8000 to the cost of a conversion.

While the aforementioned work is being done, the dash is being converted in another section of the factory. Although some dashes may seem fairly symmetrical at first glance, as in a Mustang, they rarely are. There are subtle differences and they preclude the use of original crash pads without alteration. If a factory dash is hard, as with the Raptor, a reversed version is made in fibreglass. If a car has a padded dash, a fibreglass base unit is made and covered with a thin foam sheet and tough vinyl skin that are heat shrunk onto the base together. The materials can be varied to create the same feel as the factory-fitted dash.

Depending on the car, some of the inset panels that fit into the dash may be able to be swapped. Those that can’t are either modified or replicated in plastic injection moulds or fibreglass and finished to match the colour and texture of the originals. The skill with which these processes are done at Crossover is remarkable and has taken years of research and practice to achieve. Craig explains that he even learned techniques from theatrical prop builders, before adapting these to Crossover’s conversion production processes.

RUNNING HOT AND COLD

Under the dash climate control systems have to be altered to fit the swapped layout. Again, the goal is to keep as much of the factory system as possible. This keeps costs down, but the key reason is that factory systems work. The more they’re changed, the greater the chance that items such as airflow control flaps and actuators may not work properly, with the result that overall system performance might be degraded.

Craig also pointed out that modifying one component can create a flow-on effect that calls for even more modification. "It can get out of hand. Some people simply fit units from other cars because it’s easier, but when someone buys a late model Mustang, they don’t want a Falcon heater", he says. Ensuring dual-zone climate control systems work as they did from the factory is a further challenge.

Consoles also need to be converted, although here owners are more inclined to live with the American layout. For instance, hand brake levers are often left in the original positions and sometimes gear levers are also. This is the case in the Mustang, but in the Raptor the gear selector and cup holders have been swapped to mirror the American arrangement. In the Ford GT, the gear shifter and hand brake lever have also been swapped.

Another challenging aspect of converting a modern machine is swapping headlights. Modern beam patterns are very complex and can’t just be swapped from side to side; they require modification to comply. Crossover doesn’t want to say exactly how they do this but the results have to be tested at an independent lab to ensure compliance. At between $35,000 and $55,000, Crossover conversions aren’t cheap, especially compared with conversions done in Asia, however they’re of the very highest quality and there’s no shortage of customers lining up. You can find out more at crossovercarconversions.com.au or by calling 03 9753 5822.

SOME THINGS NEVER CHANGE - BUT SOME DO

Converting a car from left to right is always the same in broad terms. Unbolt all the things on the left and make whatever modifications are needed so that they can be bolted back in place on the right-hand side. Not surprisingly, this is easier said than done. And in these days of ever increasing vehicle complexity, the process is more complicated than ever. The basic groups of components that need modification for a conversion are shown on the list below.

– Firewall

– Steering column/steering rack

– Pedals and hydraulics

– Wipers

– Dash and instrumentation

– Behind dash components

– Indicator and other column

– mounted control levers

– Console

– Wiring

– Lights

– Gear selectors

– Hand brake

– Seats

– Doors

– Mirrors

– Glass

1. MODERN MUSCLE

Most of the vehicles on the Crossover Car Conversions floor are modern American V8 classics, from the Ford GT supercar and Shelby Mustang through popular GM product such as the ‘Bumble Bee’ Camaro.

2. INTERIOR STRIP

When they arrive fresh off the boat, the tiller is obviously on the left. The first step undertaken is to strip out the interior. Here, the doors of a Ford Mustang are gutted before moving on to the delicate dash removal process.

3. ACCESS ALL AREAS

Removing the powertrain, including engine and ancillaries along with gearbox and exhaust, allows unfettered access to the body structure. Certain brackets are ground off, others are rewelded for the RHD application.

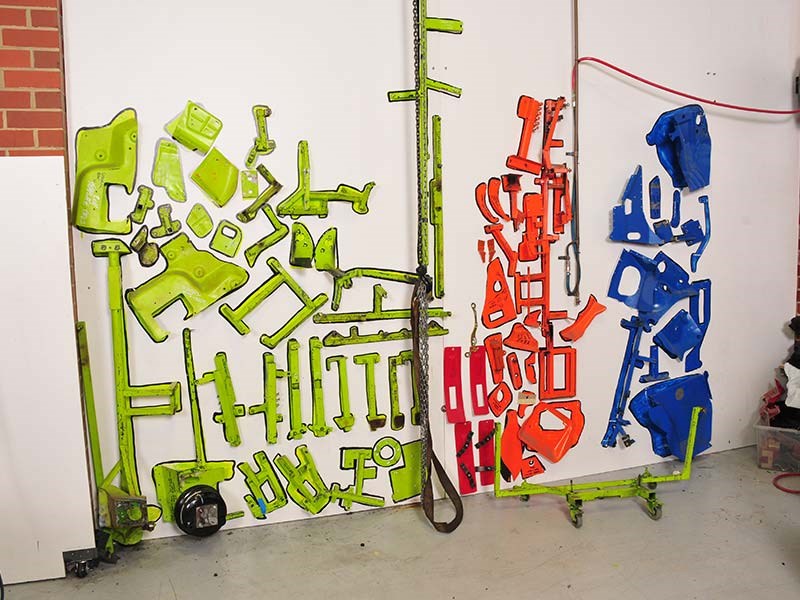

4. JIGSAW

The above templates provide a guide for the converters on every job. Green is Mustang, orange is Camaro and blue is Raptor. The second image shows the new metal sections welded in place.

5. DANCING JIG

Dashes are mounted on assembly jigs and stripped with all parts stored in racks. When all the parts have been removed from the factory steel frame the bracketry is cut off and welded to the opposite side. Note that the thick section of the main bar is now on the right, and how the rust on the factory frame has been removed.

6. DASHING

New dash sections are made from, and skinned in, foam and vinyl before being coloured with specific paint. From there, the dash is returned to the interior before careful reassembly is commenced.

7. FINAL FIT

Indistinguishable: Completed right-hand drive Raptor interior looks as though it’s come straight from the showroom floor. The amount of wiring alteration necessary varies from car to car and also in relation to the specific options fitted.

8. RACK UP

Modern elecronically-actuated steering racks add much complexity to the conversion process. This image shows high quality, finely detailed rack replacements, the upper unit for a Camaro and the lower example for a Mustang.

9. REGO RUN

All sorts of things have to be changed to meet ADR specifications. Items such as weight sensors for children must continue to work properly, while Camaros have to be fitted with a child seat anchor point.

Driver and passenger front seats often have different features and SRS systems must comply with local ADRs. Red side lights also have to be replaced with amber to meet local standards, although why it matters is beyond me.

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)