Valve chatter - Blackbourn 418

|

The humble poppet valve is putting up a half-decent fight against the ongoing existential threat

One of the mates recently circulated a link to video-footage of a restored B29 bomber called ‘Fifi’ taking to the air. If you’re into serious petrol-powered machines it was fabulous stuff. Surprisingly for a bloke wedded to engines (Fifi’s four Wright 18-cylinder radials were super impressive), my takeaway info-nugget was that this aircraft had some computer-controlled systems. Way back in WWII!

No surprise though, that like all period electronic-equipment the computers relied on vacuum-tube valves. Remember valves? Invented in the early-1900s they were replaced progressively by solid-state components from the mid-1960s. While pondering the electronic valve’s demise it occurred to me that another valve with ancient origins has hung in there convincingly – the conventional engine-valve (AKA the poppet valve). Its survival was achieved despite French automotive engineer Charles Faroux’s confident assertion in 1910 that ‘our good old engine with…poppet valves is on its death bed.’

They didn’t have it all their own way though. Sleeve valves that had provided solid competition in the early stages of internal-combustion engine development took until the 1930s to finally give up the ghost. Had two-stroke engines, or subsequently Wankel rotaries enjoyed wider success, it might have been a different story altogether for four-stroke, poppet-valve engines.

While conventional valves are still on the job, the resemblance between today’s valves and their early ancestors is superficial, limited to the basic shape. The primitiveness of early engineering and metallurgy left valves, particularly the exhaust valves, vulnerable to the mechanical stress of high-frequency impacts with valve seats and the thermal stress from hot exhaust gas. I can recall reading in the yellowing pages of an early Morris Cowley owner’s manual that engines should be de-coked and valves freshly lapped-in at 1000-mile (1600km) intervals. Picture the intrepid interstate traveller pulled over beside the Pacific Highway, the bonnet of his Morris raised, ferreting around in the boot for the tin of lapping paste…

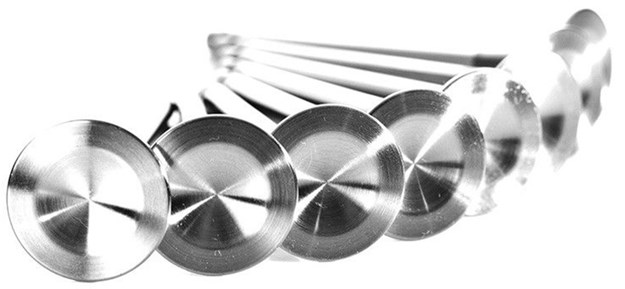

Since then we’ve obviously seen valve-design evolve dramatically including the use of improved alloys like stainless steel, inconel and titanium. Then there’s the sexy stuff like exhaust valves featuring sodium-filled hollow stems to aid heat dispersion. As well we’ve seen multi-valve set-ups of smaller lighter valves, that give improved combustion and more controllable high-rpm operation, largely displacing traditional two-valve designs. As a result the trusty poppet valve is still clattering away happily in a combustion-chamber near you.

Clearly much has also changed in valve actuation systems. While we still need to drive the camshaft at half crankshaft speed, the drive method has often swapped between gears and chains over the decades, more recently favouring toothed timing-belts. Camshaft location and twin- versus single-camshafts have been a moveable feast as well. The game-changer though has been the introduction of variable valve-timing (VVT).

Remember when your new race cam gave you heaps of top-end boost but made your motor idle like a spluttering pig? Not now – it’s the best of both worlds with VVT.

Now comes amazing news from Tech-head website New Atlas (search ‘digital valves’). A British outfit, Camcon Automotive, is developing a system that operates valves individually using digitally controlled electric actuators.Individually variable timing, lift, duration, or even whether a particular valve operates at all on a given stroke, is part of its gobsmacking schtick. Starting can be made easier by decompressing some cylinders. A brief performance boost could come from switching to two-stroke mode. Highway cruising could use a super-economical 12-stroke mode, with individual cylinders taking rest breaks in turn.

Without wanting to put the mockers on Camcon’s project, playing around with a valve’s behaviour means you need to know precisely where its piston is at each given moment. So the system relies crucially on the performance of its crank-angle sensor. Whoa! Now they’ve not been exactly 100 per cent reliable, have they?

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)