Workshop advice: car fuel systems explained

|

|

|

|

|

|

|

|

|

|

One of the keys to a smooth and reliable car is the right fuel system. Paul Tuzson explains

|

|

Advice: Fuel systems explained

|

Car fuel systems explained

FUEL PROOF

When it comes to motive power, engines generally get all the attention. However, the fuel system keeps the whole show on the road, so to speak. When building or restoring a car, there are some decisions to be made about storing fuel, getting it from the rear (usually) up to the front and then into the engine, where it’s converted into that shove in the back that we all enjoy so much.

Top tips:

1) A smaller carburettor will often provide more torque and better all-round performance.

2) Don't expect massive power increases from changing individual components.

3) Working on a fuel system can be extremely dangerous. Ensure there are absolutely no leaks in a newly installed system.

4) Fuel lines should be routed away from exhause systems. We see people who have run them together.

1

KNOW YOUR FUEL SYSTEM CONCEPTS

Imperial AND Metric units 1psi is about equal to 6.8947kPa or 0.0689 bar. 1lb per hour is 453.5924 grams per hour and with a specific gravity of 0.739 equals 10.2299cc per minute. 1 litre equals 0.2642 US gallons or 61 cubic inches. Have a calculator handy.

Venturi Effect refers to the pressure reduction that occurs whenever flow of gas or fluid passes through a restriction.

Downdraft/sidedraft refers to the axial alignment of the primary venturi tubes. Depending on the system, sidedrafts can offer better paths to the inlet valves than a centrally mounted downdraft unit.

Primaries & secondaries: Primary venturis, also called barrels, are dedicated to low-demand operation like cruise while secondaries contribute flow in high-demand operation like acceleration.

Double Pumper is a proprietary term that relates specifically to Holley carburettors that have two acceleration-enrichment pumps, one for the primaries and one for the secondaries.

2

FURTHER CLASSIFICATIONS

Because most carburettors are fitted to older engines, or are from America, maximum flow figures are often expressed in cubic feet per minute (cfm). Maximum flow should be carefully matched to the air requirements for your engine, which can be easily calculated by the following formula:

Displacement in cubic inches x RPM

3456

x volumetric Efficiency = cfm

A fast-revving Chev serves as an example:

350 x 7000 x 0.85 = 602 cfm

3456

3

SECOND CHOICES

In general, a single-barrel will only pass enough air to match engine requirements across a limited rev range. A broader range of operation is made possible by extra, or secondary, venturis that open when higher revs demand more air.

The means by which the secondaries are opened is yet another point of carburettor classification that has to be considered.

In vacuum secondary carburettors, the secondaries are opened by a vacuum signal from the primary venturis (not from the manifold). (09) In mechanical secondary units, the secondaries are opened by throttle position alone. (10)

Holley offers the best general explanations of the conditions to which vacuum or mechanical secondaries are best suited:

As a rule of thumb, vacuum secondary carburettors work best on:

– Relatively heavy vehicles

– Street gearing

– Automatic transmission

– Engines built more for low-end torque

Conversely, mechanical secondary carburettors seem to work best on:

– Relatively light vehicles

– Strip gearing (4.11 or numerically higher)

– Manual transmission

– Engines built more for top-end horsepower

Websites and catalogues provide a wealth of information on how particular carburettors work and what suits what.

4

KEEPING IT SIMPLE

Carburettors are classified by their various forms. Downdraft and sidedraft were explained above (#1 Know your fuel system concepts).

Most engines are set up to use a particular type and replacement units will generally have the same configuration. However, this doesn’t have to be the case.

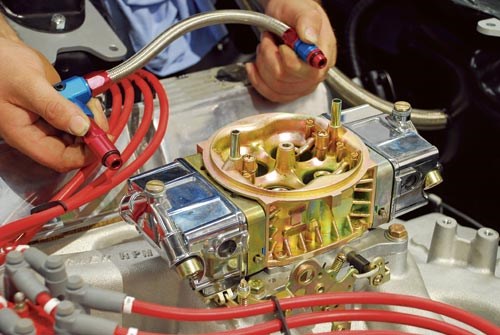

There are manifolds and adaptors available that allow different types of carburettors to be utilised on engines and in cars not originally designed for them. This supercharger blowing through a Holley into a custom manifold (above left) is one example.

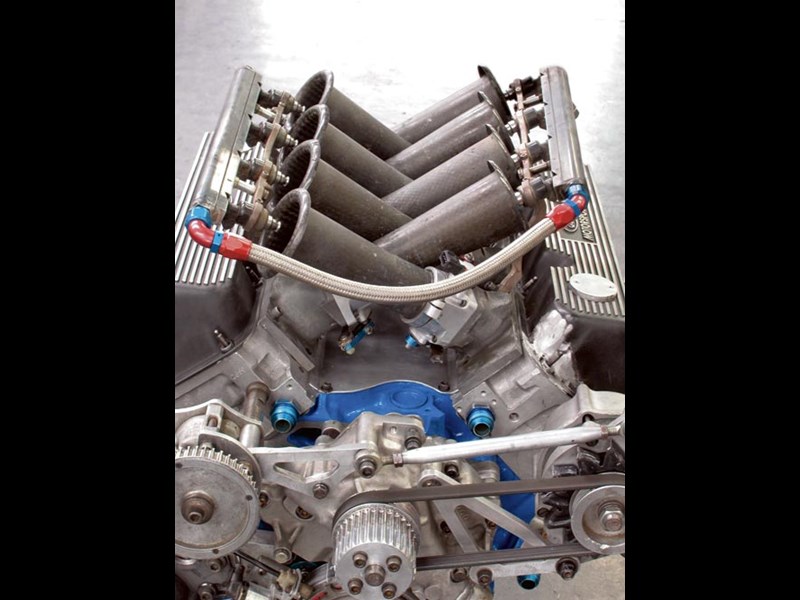

A further principle classification is based on how many barrels a carburettor has. Single, double and four-barrel types are the basic designs. These fundamental types of carburettor can be combined to create the number of barrels required on an engine. Many inline sixes came from the factory with single-barrel downdraft carburettors. Replacing one of these with a manifold that allows three double-barrel sidedrafts to be fitted (above right) would improve performance considerably.

5

INJECTION

Fuel injectors can also be classified by their physical form.

Top-feed injectors (above left) are the type fitted to Australian cars such as Commodores and Falcons. Fuel is fed into them axially from the top.

Side-feed injectors take fuel laterally. The fuel rails supplying each type are completely different.

Older-style injectors have nozzles with needles. Newer types have discs with holes in them to control flow (above right).

Fuel flow through an injector is expressed in either pounds per hour or ccs per minute.

The other important factor in choosing an injector is electrical resistance, or impedance.

Some Japanese injectors are low-impedance types with a resistance of 2-4 ohms across the connectors. They pass quite a large amount of current so they operate very quickly, but the circuitry used to drive them is more complex. These are also known as ‘peak and hold’ types because, after the initial burst of high current, a considerably reduced current is used to hold them open to avoid overheating.

Most top-feed injectors have a resistance of between 12 and 16 ohms, which makes them high-impedance. They are also known as saturated injectors, but it should be noted that low-impedance top-feed injectors are available. Saturated injectors don’t operate quite as quickly as peak and hold types, but they stay relatively cool in operation.

Aftermarket management systems can equally run either high- or low-impedance types, but factory management systems are specifically designed for one or the other. The wrong ones simply won’t work and may cause damage, depending on the components.

There are formulas to find the flow rate of each injector in pounds per hour needed to support a particular power figure, or to find the potential power available from a set of injectors from the flow rate in pounds per hour.

But there is also an extremely good on-line calculator that does all this at: injector.com/injectorselection.php

Another site worth a visit is capa.com.au/library_injectors.htm

6

MECHANICAL PUMPS FOR CARBURETTORS

OE mechanical pumps operate at around 3-5psi while aftermarket street/strip mechanical units operate in the 5-7psi region. Dedicated competition mechanical pumps create pressures as high as 10psi. Depending on model and brand, these pumps supply between 80gph and 170gph.

If you already have a mechanical pump in place and just want to upgrade your system, bolting a more highly rated pump in place is a quick, easy and relatively inexpensive way to get more fuel.

Again, there are formulas for relating power and flow based on the idea that making one horsepower for one hour takes 0.50-0.55lb of fuel. If you have a figure in mind for horsepower, then the following formula should tell you the fuel-flow rate required in gallons per hour (GPH):

Desired Horsepower x 0.55 = gph required

6

Unfortunately, this won’t be correct because the nominated flow rates of many pumps are established under low-pressure, free-flow conditions. Flow is inversely proportional to pressure. This means that, as pressure rises, flow decreases. In fact, restricting flow is how a pressure regulator increases pressure.

As an example, according to this equation, if you wanted to make 650hp you’d need a pump that delivers 59.6GPH. With a free-flow rating of 110GPH, a Holley Blue (electric) seems like it has ample capacity. However, at 9psi the published flow rate for this pump drops to 70GPH. Although this is still enough according to the equation (and practical experience), it doesn’t consider any other losses in the system. In fact, 650hp or a bit more is getting to the limit for a Holley Blue.

7

INCREASING THE SPREAD

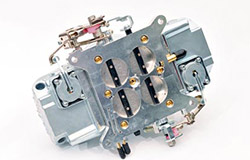

To better match the size of venturis to engine operating conditions, carburettors with smaller primaries and larger secondaries were introduced.

The smaller primaries increase throttle response and torque at lower revs. However, when the larger secondaries are needed throttle response isn’t so important. At wide-open throttle, the only thing that matters is getting maximum air and fuel into the engine.

Four-barrel carburettors with larger secondaries are known as spread-bore types because the area covered by the outlets underneath spreads out towards the rear.

Carburettors with same-sized primaries and secondaries are called square-bore types.

Manifold openings are specific to each type and, although adaptors are available, it’s best to use the correct manifold (above).

8

ELECTRIC PUMPS

Mechanical pumps have to pull fuel up to the engine from the rear, whereas electric pumps (above right) mounted beside or in the tank push fuel toward the front. This is a much better arrangement. Also, if one pump can’t deliver the required flow, another can simply be mounted next to it with the outputs feeding into one line (above left).

Electric pumps for EFI create pressures ranging from around 50psi to considerably more than 100psi, much more than mechanical pumps. These high figures for EFI pumps ensure that the fuel pressure is maintained in the lines right up to the regulator.

9

PRESSURE REGULATORS

Pressure regulators reduce excessive pump pressure to appropriate levels.

Simple regulators (above right) have adjusting screws and lock-nuts on top of them. Better types have manifold reference ports that allow manifold pressure to assist in determining the correct fuel pressure. Get the highest quality you can afford because cheap, restrictive regulators have been known to kill engines.

There are also rising-rate regulators (above centre) for use in boosted applications. These are needed because boost pressure in an engine manifold resists fuel flow out of the injectors in an EFI system. Manifold boost pressure directed to the reference port on a rising-rate regulator acts to increase fuel pressure and compensate for the resistance to flow.

10

FUEL LINES

Steel fuel lines are defined by external diameter. Flexible lines are defined by internal diameter. Aftermarket braided and specialised lines intended for use with aluminium fittings (above right) are defined by the dash system. It’s not directly comparable to imperial sizing, but the internal diameter of a -4 braided line is a bit smaller than a 5/16in stainless hard line and a -6 braided is a touch bigger than a 3/8in stainless line.

Steel factory fuel lines (above centre) are often 5/16in diameter, but replacing these with 3/8in lines can be beneficial if a motor has been substantially improved.

Bigger lines call for more powerful rear electric pumps. Flexible lines (right left) are easiest to fit, but must be well-supported.

11

FILTERS

Fuel filters can be really cheap or fairly expensive, but not having one at all can be the most expensive choice. Injector nozzles are susceptible to contamination from very small particles, and so are needle and seat assemblies in carburettors.

Inexpensive disposable filters work well provided they’re large enough to pass the fuel required. In lines feeding higher performance engines, inline aftermarket filters (above right) are best. These can be dismantled to replace disposable elements or clean reusable ones. Some high-end set-up pumps (above left) have integrated filters.

12

TANKS

Tanks can get knocked around badly and suffer corrosion. The good news is that they can be repaired, but it can be pricey.

For almost the same money, reproduction OE steel tanks (above #1) can be had. Rare Spares has them, but they’re only made for more popular models like Falcons and Toranas.

There are lots of race tanks available (above #2), but any fitted to a road car have to comply with the model’s ADR specifications.

Surge tanks are often part of race/performance set-ups. These are used because fuel pick-ups in fast cars can become uncovered as the fuel moves around due to inertia. If this happens fuel supply to the engine will become interrupted, which can lead to engine damage. The solution is to have multiple ‘lift pumps’ to draw fuel from different sections of the main tank and feed it into a smaller surge tank containing a pick-up that never becomes uncovered.

In cars that run the quarter-mile, fuel tends to become concentrated at the rear of the tank, so aftermarket tanks intended for strip racing have pick-up points low on the tank at the rear.

However, on the street this is a very vulnerable location for attaching fuel lines. A bump with another car could break off the fittings, turning what should have been a simple exchange of addresses into a hydrocarbon bonfire. Better to connect lines to tanks at the front in a protected location and run internal pick-ups to the rear of the tank.

This brings us to custom fuel tanks (above #3). The advantage in having a tank made is obviously that it can be tailored to the exact application. Many custom (and good aftermarket) tanks are built with internal baffles that resist fuel movement during cornering, braking and acceleration.

Meracell foam has long been a strategy for minimising fuel movement. It’s so porous that a tank completely filled with Meracell foam loses only three per cent of its storage capacity. These days there are other foams compatible with a broader range of fuels.

CONTACTS

melbourneperformance.com

rarespares.net.au

eagleautoparts.com.au

capa.com.au

vpw.com.au

facebook.com/MikesDynos

Dalton Automotive (03) 5224 2708

injectorsonline.com

speedproshop.com.au

tttperformance.com.au

WHAT YOU'LL NEED:

- A fuel tank; original, original repaired, aftermarket off-the-shelf, or aftermarket custom

- A fuel pump; engine-driven mechanical or electrically driven

- Fuel lines; original or new steel hard lines, flexible braided or flexible rubber

- Aftermarket in-line fuel filters abound and should always be fitted

- A pressure regulator is essential for a system to run correctly

- A carburettor or set of injectors to convert fuel into what an engine requires

- A flaring kit with fittings for making high-pressure double flares

- Good open-ended or flare-nut spanners, or aluminium open-enders for alloy fittings

- For more modern EFI applications, a fuel-line disconnection kit may be needed.

HOW LONG WILL IT TAKE:

If the linkages and cables match, a carburettor swap can take as little as half an hour. A full EFI conversion can take days of uninterrupted work or more. And then there’s everything in between.

HOW MUCH WILL IT COST:

4-Barrel Carb

A new four-barrel carburettor designed to replace an original equipment version might cost around the $500 mark.

Performance

A more performance-oriented model will probably be several hundred dollars. While a big race-oriented carburettor can cost as much as $1200. If required, a different manifold will add perhaps $300-$500 to the cost for a mild performance type.

Mechanical Pump

A standard mechanical fuel pump can cost as little as $60. A performance mechanical version will be up around $200.

Electric Pump

A Holley Blue electric fuel pump will be about the same ($200).

EFI Conversion

Converting a previously carburetted system to EFI can be a pretty big handful of thousands of dollars. Now, however, there are fully inclusive kits for about $3000 like this Holley Terminator.

*****

More reviews:

> Workshop: Car tyres explained

Search used:

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)

.png)