Shedmasters: Neway Wheel Repairs

|

|

|

Shedmasters: Neway Wheel Repairs

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hi-tech production line comes as a big surprise

If you thought repairing a damaged alloy wheel was just a bit of sanding and a lick of paint, think again. The professionals over at Neway Wheel Repairs have a whole different take on the process

When was the last time you saw someone repairing an alloy wheel? Up until recently, to us the idea brought up images of someone using power tools, some filler, and a bit of spray paint. However, as we recently discovered, there is another way which involves going very close to remanufacturing the wheel.

Having recently spent what we suspect is a small fortune on a massive upgrade, Neway Wheel Repairs in sunny Melbourne has adopted a sophisticated production line system to handle the massive volume of work that comes its way.

Above: Trent and Kyle with some of their handiwork.

"Our family has been doing this for over 60 years, says Trent Gilbert, who runs the show with brothers Kyle and Jai. "That’s since 1950. Our grandpa, Bill, and partner Tony O’Kane used to work at Austral Wheels and then started Neway.

"Their main business was wire wheel manufacturing – they were the biggest before you could get this stuff out of India and China. Dave (who works at the Neway facility) still does the spoked wheels, but we’ve stepped away from that and do the new stuff – alloy wheel refurbishment.

"We’re busy. We do a lot of insurance work and have three vans on the road picking up work from all round Melbourne. So if your car is in an accident, we’ll go and pick up the wheels from the panel shop."

The new machinery was installed during 2023.

"We travelled the world," explain Trent, "including America and England. It’s a niche business here, but over there it’s bigger and we needed to find the best equipment.

"We flew people out from overseas and got them to install the machinery – it’s the best you can buy at the moment." The installation took a month and was effectively a custom build to fit the space and meet local regulations.

So what’s the process? "You bring in a damaged wheel, we’ll strip the tyre off and spin it up to check that it’s round. Any buckles are taken out.

"Once that’s done we load a basket that takes 30 wheels. It goes in to a tank of locally-bought chemical used in a hot strip. That takes roughly five hours.

"It brings the wheel back to the substrate, which is just the alloy.

"The benefit of that is you’re working from start and not dealing with anyone else’s paint. This is the point they get to when they’re first manufactured, then you get to the powder coating. It’s the same process as OEM.

"Most of the time we can fix a damaged wheel. We don’t weld very often and we don’t fix cracks. We can re-roll and straighten wheels and fix surface damage. We can remachine them and paint them any colour you want."

After stripping, the wheels are blasted with stainless steel shot in part to give the initial powder coat something to stick to.

The colour is a three-stage system: the primer is powder, the colour is water-borne paint and then clear is and acrylic powder. It’s the same way they come out from the factory.

"It takes four days from start to finish – it’s quite a process to do it properly," says Trent. "This is not a touch-up job as we can’t go over any old stuff. It’s a full remanufacture."

The system is designed to have a couple of runs of 30 wheels on the go, at different stages, and to complete a strip overnight.

Handling the system is partly about traffic control, matching up wheels into batches so the production line flows as well as possible.

The wheels travel through an oven and emerge at around 220 degrees so the primer can be applied hot. Doing it this way allows the primer to ‘flow’ resulting in an ultra-smooth finish. They then get baked and move on to the colour stage.

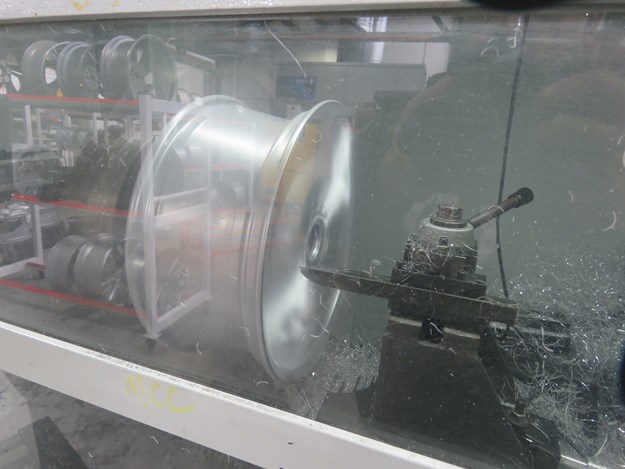

The process varies a little for machine-finished wheels, which are taken up to the colour stage and then put on the CNC for a diamond cut on the face. Then they get a clear coat. Demand is such there are two machines going at any one time.

"The last time we upgraded was around five years ago and we grew out of it in a year," says Trent. "This time we’ve gone big so we don’t have to do it again.!"

There are a lot of moving parts. Nevertheless, Neway cheerfully tackles custom jobs for anyone looking for a unique finish.

You end up with what is basically a new wheel. After this all they need is a wash with water and a rag to keep them looking good.

Given these guys tackle wheel repair for a living, what’s their advice on getting wheels for your toy? "Get factory wheels, if you can find a set that works for you, as they’re good quality." If you’re buying aftermarket, the advice is a cheap wheel is a cheap wheel, so expect to pay thousands rather than hundreds for a decent quality set.

OUR WHEELS

We had a spare set of 10-spoke BMW M wheels for our E39 540 Sport that were badly in need of refurbishment. They had lots of kerb rash, along with the usual stone chips and nicks.

The finished product is stunning – almost too good to put back on the car!

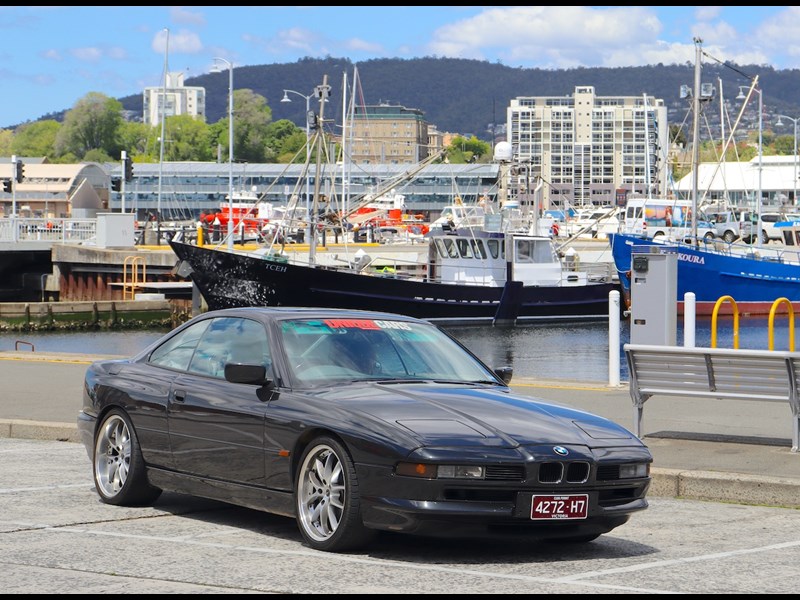

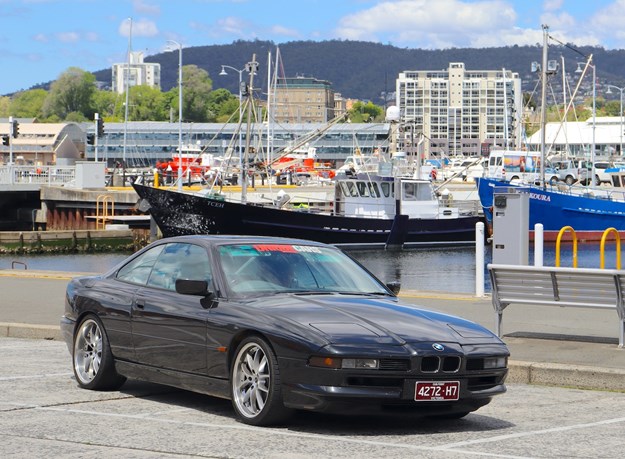

Meanwhile Neway also managed to roll out a bend in a rear ROH rim on our 850. However we plan to get the extra set of 10-spoke factory wheels done up and sling those on this car.

Neway Wheel Repairs contact:

Tel 03 9457 3141

11 Beatrice Ave, Heidelberg West, Vic 3081

Email: repairs@newaywheelrepairs.com.au

Instagram: @neway_wheel_repairs

Facebook: facebook.com/NewayWheelRepairs

(Look for the videos on the repair process.)

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.JPG)

.JPG)

.JPG)

.jpg)

.png)