Project Challenger restoration - part 2

Cast numbers indicate cold weather block

Cast numbers indicate cold weather block

NFG - says it all

NFG - says it all

Green texta marks indicate area of crack through main web

Green texta marks indicate area of crack through main web

Cold weather block had extra material in the main webs for added strength

Cold weather block had extra material in the main webs for added strength

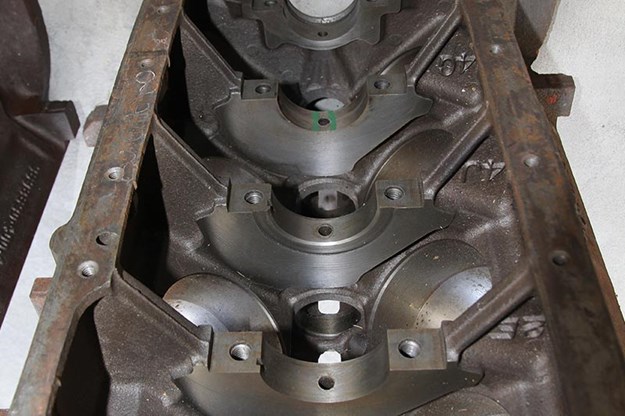

Good block - note less material in the main webs

Good block - note less material in the main webs

|

|

|

|

Cast numbers indicate cold weather block

|

|

|

|

NFG - says it all

|

|

|

|

|

Green texta marks indicate area of crack through main web

|

|

|

Cold weather block had extra material in the main webs for added strength

|

|

|

Good block - note less material in the main webs

|

How Chris Beattie went in search of the ultimate big-block and came home with a 130kg coffee table

"You know that block you dropped off for crack testing mate?"

"Yeah." "It’s buggered." "Bugger."

Thus ended my initial plan for the rocking horse rare 400 cu in Dodge factory block that I’d discovered purely by chance in a Melbourne wrecking yard. I’d gone in search of any 400 block in good nick as the basis for a ballistic 500-plus cu in tyre-shredder for our Mongrel ’70 Challenger (read part one here). All the experts reckoned the 400 offered the best combination of massive bore (4.342in – one of the biggest in the business) and a stroke as big as you’d want. With an under-square 4.150 steel crank, I’d still end up with a Godzilla-like 500 cube motor that would rev all day long and be good for around one hp per cube without any stress whatsoever.

So I’m looking at the bare block on the workshop floor and I notice some big raised casting numbers on one side. Flicking through my copy of Mopar Motors for Morons, I see a picture of exactly the same block. The caption said: "If you find one of these for sale, try and keep a straight face coz they are rare as …" or words to that effect.

Cast numbers indicate the cold weather block

Cast numbers indicate the cold weather block

Turns out it was one very rare ‘Cold Weather Block’, with lots of extra meat in all the right places, including the decks, bores and main bearing saddles. Only a couple of thousand were cast back in the early 70s and serious Mopar hot-rodders would give their firstborn to get hold of one.

So after nonchalantly checking the bores and giving it the once-over, I turn to the bloke in the overalls.

"Dunno mate, looks like it’s gonna need some work and ..."

"Eight hundred bucks or piss off." "Done!" But after snagging what I thought was the buy of the century, a few weeks later I was more than a little deflated to hear that it had the Mopar equivalent of the Grand Canyon running through its centre webbing. It was almost impossible to see, but crack testing had revealed the fatal fissure.

| Read next: 1970 Dodge Challenger Reader Resto

Cold weather block had extra material in the main webs for added strength

Cold weather block had extra material in the main webs for added strength

So, I now had what will become an $800 130kg conversation piece/coffee table, and was still no closer to building Mongrel’s killer big block.

It was a lesson learned though. Sort of.

| Read next: Dodge Challenger buyer & value guide

A wise man once said that two heads are better than one. He also drove a V8

A wise man once said that two heads are better than one. He also drove a V8

I started the search again and was almost going to get hold of one in the US when another 400 turned up on Ebay. It was over in Perth, had sat in a paddock growing rust for most of this century, but the seller bloke reckoned it was otherwise in pretty good nick. He was actually a proper engine builder and guaranteed in writing that he’d refund the $1K price if it turned out to be a matching coffee table to my previous purchase.

Happy to report that it passed the crack test with a 10 out of 10 and we even trial bored it to make sure it would handle a 40 thou overbore.

| Read next: Dodge Hemi Challenger review

So I’m now scouring the internet for the rest of the bits needed to turn it into a howling, fire-breathing beast. Fortunately a fair chunk of the web seems to be dedicated solely to offering me options to spend lottsa dough on Mopar go-fast bits. There are alloy heads in all shapes and sizes, and enough cranks, rods, pistons and cams to cater for all tastes. Main thing is it all has to work well together. All the bits have to get along, otherwise it could be a case of pissed ‘n’ broke, as they say in the game.

The block now wears an ‘NFG’ tag - says it all, really

The block now wears an ‘NFG’ tag - says it all, really

And, of course, there’s still the small matter of the rest of Mongrel, which as I write this, consists of several million seemingly unrelated parts that used to be a 1970 Dodge Challenger taking up space in mate, Max Hayes’ resto shop, otherwise known as Hayes Garage.

Personally I blame Max. He’s offered nothing but encouragement throughout the project to date, when what I probably really needed was a dose of reality delivered by a shifter around the head.

Max is determined to keep Beattie’s dream alive

Max is determined to keep Beattie’s dream alive

Actually, Max is about the best there is as far as resto and panel repairs goes, so at least I know the body will be in good hands. If you need a mudguard for your 1918 Pierce Arrow, I reckon Max could whip one up for you out of some corrugated iron, just using his memory and a pair of pliers.

Happy days.

Classic Australian Family Car Value Guide home page

Muscle Car Value Guide home page

Japanese Classic Car Value Guide home page

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)

.jpg)