1966 Corvette: Reader Resto

John Strano's 1966 Corvette

John Strano's 1966 Corvette

Good, straight body to start with

Good, straight body to start with

Good, straight body to start with

Good, straight body to start with

Good, straight body to start with

Good, straight body to start with

.jpg) John's resto project went way more than skin deep...

John's resto project went way more than skin deep...

.jpg)

.jpg) John didn't stint on the interior trim. A classy result

John didn't stint on the interior trim. A classy result

.jpg)

Final polish and the badges are on. Job done.

Final polish and the badges are on. Job done.

Final polish and the badges are on. Job done.

Final polish and the badges are on. Job done.

|

|

John Strano's 1966 Corvette

|

|

|

Good, straight body to start with

|

|

|

Good, straight body to start with

|

|

|

Good, straight body to start with

|

|

|

|

.jpg)

|

|

John's resto project went way more than skin deep...

|

.jpg)

|

|

John didn't stint on the interior trim. A classy result

|

|

|

|

|

Final polish and the badges are on. Job done.

|

|

|

Final polish and the badges are on. Job done.

|

|

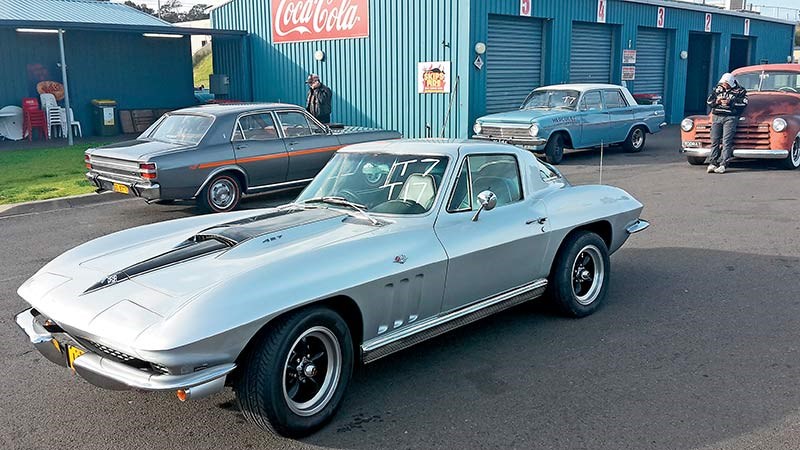

A simple glance at a drawing 20 years ago started John Strano toward restoring his own Corvette C2

John Strano's 1966 Corvette

Growing up in the early ’70s, I’ll never forget the first time I saw a drawing of a C2 Corvette Grand Sport. That car was the best-looking thing I’d ever seen and it hooked me. I was already mad about cars and working on them, and at the time I was working on turbocharging an XU-1 Torana, but that Grand Sport sparked something in me. Some might call it love.

The dream of owning a C2 Corvette stayed with me for the rest of my life, in the back of my head; I found myself at 45 and still wanting one. I wasn’t sure about making the big step though, because of a few reasons. Firstly, I didn’t just want any old C2, I wanted a matching numbers car, a tidy right-hand driver, and then one day, a C2 popped up in the classifieds which caught my eye. It was in reasonable condition, the conversion was a good job, so I bit the bullet and bought it.

Once I got the car home, I took it to a good mate of mine, Ned from Hercules Competition Engines, and we came up with a plan for my car. I wanted a really individual Corvette and one with a mountain of torque. In the first 60 feet at the lights it’s all about torque off the line and Ned and I wanted to get the Corvette to put out 500lb/ft at 3000rpm. That was our goal. But my car was the small block L79 engine, not the 427 big block. With the Grand Sport as inspiration, we accepted the challenge.

I gave Ned the car for three months with the plan that I wanted that big torquey engine which he said would require a four-inch stroke. ‘Whatever you have to do, do it,’ I said. He pulled the engine out and got started. The heads came off, he massaged them, and match-ported the cast iron heads to the manifold. The camshaft was his own design, the carburetion was worked over; same with the timing, spark and distributor. He also has a special secret design of the oil galleries – which he hasn’t even explained to me – but that’s one of his keys to getting all the torque he wants from an engine.

Down the driveline, the Tremec ratios weren’t right for what we were trying to achieve. Ned suggested a two-speed Powerglide and we settled on that, a much more robust gearbox for the output given the stress it would put on everything. I spoke with Motorcraft in the US and they advised me on some special shackles which encase the universal joint to add strength and make the car a lot safer in case all that torque broke anything. They’re about $600 each and a great piece of machinery which Ned insisted on.

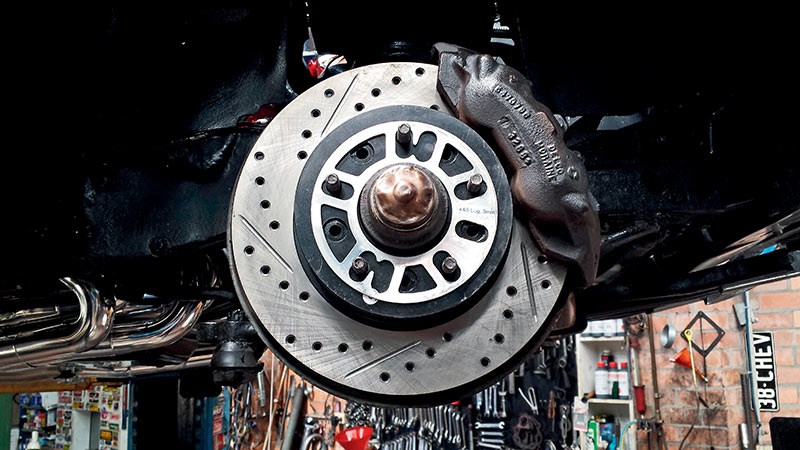

We did the brakes with cross-drilled rotors and a specific type of hard-to-find performance pad from Eckersley in the States for this kind of car. The calipers are four-piston and are well up to the task of pulling her up. The suspension got upgraded; they pulled all the front end apart and replaced the tired old bushes with polyurethane. The transverse leaf spring setup which can wobble when it breaks traction is much better off with special Teflon bushes in the mounts. The steering has a factory power unit fitted to make life a bit easier too.

The paint on the C2 was pretty good when I got it, but it had no Stinger bonnet. I imported one from the States, which was an expensive exercise, and while I was at it decided to do the rest of the body as well. Stinger bonnets are so hard to get, mostly because they take a month to make one; that’s what made it expensive – and I’m glad it did because it really sells what my car’s about. The body was sanded back to the fibreglass, every inch was prepped and painted and I was really happy with the result. George from TGM Panel Beating & Spray Painting did all the work and said it didn’t need a drop of filler or any beating, which certainly made his life easier!

Indoors, I wanted something nostalgic that suited the era a bit better and found some clocks with the nice ’60s-style font. It’s another detail which I’m very pleased with. We were concerned with the kind of heat the engine might put out in terms of damaging the paint or panels, so Lewis at Moore Style, the motor trimmers in Dural NSW, had a special heat-proofing material laid down to handle it. It took about two weeks including the seats and door cards. I actually got the 427 badges put onto the door cards just to keep that little wink to the capacity being the same as the big block, even though it’s a small block.

All in all, Ned and I are stoked with the C2. It’s definitely got a lot of ‘us’ in it, and when we got the car all packaged up and sitting on the dyno, he was very surprised with the figure he got. I’ll never forget it. He rang me and said, ‘You need to come down and turn the dial. You’re going to be a happy man.’ We stood together in the room and wound the dial up on the dyno and I couldn’t believe my eyes. That little number on the screen in front of me was like winning the jackpot – the L79 motor hit 3000rpm and was already putting out over 500lb/ft of torque and it just got bigger and bigger. You couldn’t slap the smile off my face. Did I mention the 500lb/ft of torque? I was pretty pleased with that particular result. We took the Corvette to Eastern Creek recently to have a go on the drag strip and managed to crack a 12-second time at 105mph. Mission accomplished.

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)