Reflecting on the 4x4 XY Falcon ute - Blackbourn 427

|

|

|

|

|

Apparently the project to build one batch of 4x4 XY Falcon utes back in the day wasn't all beer and skittles

The beautifully restored XY Falcon 4x4 ute in the Readers’ Rides feature in Unique Cars issue #426 caught my eye. Given that owner Jimmy Hodges bought it for $1250 and left it "under a tree" while he figured out what to do with it, it’s obvious that he put in a heap of work and overcame many challenges to bring it back to showroom condition.

| Read next: Jimmy Hodges' XY Falcon 4x4

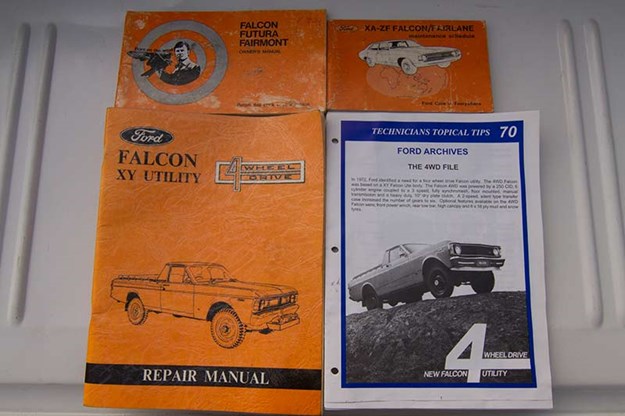

The team working on the XY 4x4 project at Ford Australia in 1970-72 also put in a heap of work and dealt with a bunch of challenges to get the thing into production in the first place. The aggro involved in sorting out the pre-production issues on the 4x4 build of only 432 units was, as they say, quite character building.

Ford’s Product Engineering team was off to a good start having just completed four one-tonne GS light-trucks for the Australian army. These flat-panel one-tonner prototypes were 4x4s powered by Falcon sixes – not light-years different from a 4x4 Falcon ute project.

The fiddly, hands-on assembly work required to build the 4x4 ute was a ‘no-go’ in the slick and sophisticated, 52-units-per-hour, Broadmeadows Assembly Plant. The Brisbane Assembly Plant at Eagle Farm, already doing the labour-intensive, low-volume build of right-hand-drive F Series light trucks for the Australian market was the logical location. As well Ford was already involved with Willys Motors in Brisbane, supplying Falcon six engines and other components for locally assembled Jeep models, meaning Willys could supply adaptors and brackets to hook the XY ute’s six up to its 4x4 driveline that shared much with the Jeeps.

| Read next: 1973 Ford Falcon XY 4x4 review

As with all new Ford Australia models, the XY 4x4’s pre-production project management was a Head Office function. Its Melbourne location at Campbellfield was a complicating factor in terms of communication and hands-on problem-solving for a build taking place more than 1700km away. So plenty of frequent flyer points were earned and the problem resolution process suffered many delays.

Although the front of the XY subframe, and the rear undercarriage, were heavily beefed up to cope with the expected off-road bashing (also to provide robust mounting points for the front semi-elliptic springs), a prototype XY 4x4 returned from an outback trial with stress cracks in the central cab area. Worse, its front axle assembly came back bent. While reinforcing the cab wasn’t a big issue, changing the axle assembly to a higher rating was. This spec change and other issues with the American supplier caused a huge delay in axle-assembly availability.

As a result of the overall delays the XY 4x4 launch, planned for 1971, rolled over into 1972. This meant it had to be rejigged to comply with new 1972 Oz design rules mandating many new features including the XA-style collapsible steering column and high-back bucket seats.

Assembly of the XY 4x4 was such a hands-on exercise, that even at Eagle Farm it wasn’t a happy fit alongside normal production. As I recall most of the 432 units ended up being built at weekends.

Heavily modifying an existing vehicle inevitably forces some unexpected compromises – an interesting example was the ute’s tyres. The original tyre/rim combo was decided early on using key tech-criteria like load factors, grip levels, speed ratings, noise levels, durability – even handsome wide-tread looks. All that was suddenly history when it was discovered that chassis mods at the rear had dramatically reduced storage space for the spare wheel. Engineers were dispatched to find something suitable to fit the shallow space. The one that slotted in was a skinny 6.00 x 16 lug-tread, cross-ply tyre. So each XY 4x4 was shod with a set of tyres identical to those fitted to Ford and Willys Jeeps of WW II. Very 1940s, very skinny, very noisy, but they met the XY’s important duty specs and, best of all, you could stow the spare.

Classic Australian Family Car Value Guide home page

Muscle Car Value Guide home page

Japanese Classic Car Value Guide home page

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)