Power Brakes SA - Workshop Profile

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

What does it take to keep the doors open over the decades? A willingness to adapt, apparently

Power Brakes SA Pty Ltd

You hear of businesses having to adapt or die as their environment changes over time, but it’s not every day you get to see a successful example of adaptation that has nevertheless managed to keep the best parts of its company culture.

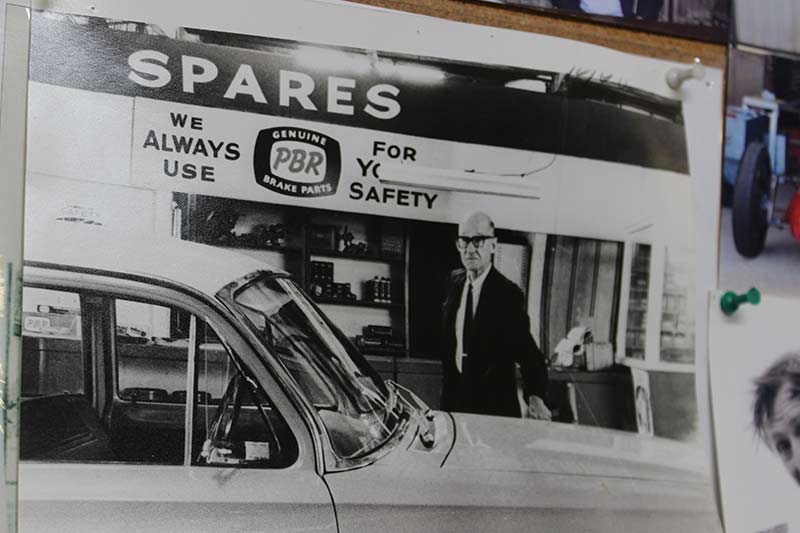

That seems to be the case of Power Brakes on the north side of Adelaide. Over the years it’s changed from a general engineering shop, to an automotive workshop and brake component machinist, to a dedicated brake service operation that now does a significant share of its business on the internet.

Derek Greeneklee is the second-generation owner and has been along for the majority of the ride. These days he describes himself as retired, though he pops in a couple of times a week, and is content to leave the business in the hands of manager Carl Hayward.

"Carl has been the Manager now for the last seven-plus years," explains Derek, "since the retirement of Mr Frank van Gastel, who was with us for 50 years. He came out from Holland in 1960. He became our General Manager until he retired in 2010."

Half a century. When you ask a few more questions it quickly becomes apparent the building is filled with long-term staffers. For example, Carl did a year or so with a local bakery for about a year out of school, then joined Power Brakes in 1979. He never left.

Clearly, the company is doing something right when it comes to maintaining staff. Derek described a time when he found himself taking over the business after his father’s passing in 1967. It was sobering and challenging.

"When he died I suddenly found myself faced with the responsibility of a business I hadn’t taken much notice of," says Derek. "I remember coming in one morning and was a bit late, and there were 12 or 15 guys sitting on the gutter waiting for me to get there and let them in, and it suddenly occurred to me I had a responsibility.

"I think at that point I made a conscious decision that unless I could create a happy working environment, I wasn’t interested and couldn’t do it."

Carl confirms that the culture remains. "I think when you look at the longevity of all our staff it tells you that Derry is a great person to work for," he says. "Most people are happy and they stay. Which is really good for the business, because it means we retain the knowledge. It’s not something you can learn in a trade school as they don’t do a brake specialist apprenticeship any more. It’s a very specialised field and you rely on on-the-job training to get the knowledge you need to do the job."

So how has the business changed since it got into the automotive area? "We started in a very humble way," explains Derek, "Initially we were repairing cars. What we became aware of was that one of the components that failed most on drum brake cars was wheel cylinders and master cylinders to a lesser extent. At that time you had to buy new wheel cylinders and they were fairly expensive.

"We were early in deciding that because we’d moved away from an engineering business where we were resleeving engine blocks, the logical thing was to say let’s sleeve brake cylinders that are corroded and worn, rather than throw them away.

"Initially we sourced brass sleeving but that wasn’t entirely satisfactory as it had a tendency to wear. Eventually stainless steel sleeving became available, so then we started to sleeve slave and master cylinders. At one stage we had 63 people on staff and 45 of those were sleeving cylinders, going back to the seventies and eighties.

"Around that period of time we started to see the introduction of Chinese imported cylinders. Where we were getting $30 for a resleeved Holden cylinder, the Chinese product came along for $8-12. Initially it was for the most popular models but eventually, as time went on, by the 1990s you could buy almost any cylinder.

"What had become a major activity for us, employing a large number of people, slowly came down to the only cylinders that we’re now resleeving are those that are unavailable because they’re so old, or they’re extremely expensive.

"We gave away working on motor vehicles and just focussed on components. So for the last 10 or 15 years I guess we’ve recognised what was going on around the world with this restoration caper, and thought well, right, we have over 50 years of accumulated knowledge and records!"

That last point is crucial. Along the way, the business has kept detailed records on the vehicles it’s worked on, right down to parts lists and numbers. That means it has extraordinary records on brake systems, dating all the way back to the 1940s.

In the meantime, the company has engaged with the very people they were competing against – China. Carl has been there several times over the years and they’re now sourcing components there, such as hose fittings some of which they sell to other brake component suppliers.

In fact, hoses have become a major part of the business. Power Brakes has two hose-making machines in-house and is selling something of the order of $20,000-worth of product a month, which, as Derek points out, is a lot given they generally cost $35-40 each.

Now a big part of the business (apart from keeping current cars going) is rebuilding and supplying new parts for restoration projects. Carl says what generally happens is they discuss the project with the owner and are very careful to check what sort of finish they’re after. It could be new, but sometimes they just want it cleaned up nicely or even left in ‘survivor’ trim, complete with the existing external rust but with fresh internals.

Despite the decades of experience, they still get fresh challenges. "This week it was a brake booster off an MS51 Crown (the coupe)," says Carl. "We had never seen one before, they’re so rare. This fella really wants it done. Sleeving the bores is fine, that’s what we do. The challenge is finding all the parts to put this thing back together, so it’s 100 per cent restored. We source parts from all over the world, so you can get the job done."

In the case of resto work, owners often post the components across for refurbishment and, in the cases of some more common models, they can offer an exchange service. Generally there is a one-week turn around for a refurbished component, though something special will take longer.

Inevitably, a significant part of the business has gone digital. "Internet has enabled us to spread our wings," explains Carl. "In the early years we only serviced our local market, mostly in a personal delivery circle. It was enough to keep us busy for many years. But then the market changed. To survive, we’ve had to go interstate and even overseas. Internet is a really good tool for reaching those markets."

Business aside, what do they get up to in their spare time? It turns out they’re both petrol-heads who love to spend hours dabbling in cars and motorcycles. For Derek, his passion is early Cooper open wheel race cars, early versions fitted with JAP engines. He has a 1952 and 1956 model.

"With modern race cars youhave to spend an awful lot of money," he says. "Whereas with older cars they cost a few bob initially, but they’re so simple, so you can do most of the work yourself if you are a bit handy and you’re not constantly putting new tyres on them every meeting, and this sort of caper. They are a lot cheaper to run."

Carl meanwhile confesses to owning a 1970 Mercury Cougar and a 1933 AJS.

So, internet development at one end, while retaining an old style mascot that has made the business instantly recognisable, and messing around with old Coopers or Mercurys.

Good luck to them.

Power Brakes SA Pty Ltd

613 North East Rd,

Gilles Plains, SA

info@powerbrakes.com.au

(08) 8261 0888

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)