3D Printing Engine Building - Delage Grand Prix racer

.jpg)

.jpg)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.jpg)

|

|

How 3D printing saved one of the world's oldest Grand Prix racing cars

What do you do when your priceless one-of-a-kind ancient Grand Prix race car blows up? Nowhere in the world is there a spare motor. Only three were ever made, and your car is the sole survivor. What are your options ? There is zero prospect of the right motor ever turning up, anywhere, no matter what the price. No barn finds, no hordes of parts awaiting Indiana Jones type exhumation. None of the attempted repairs hold. No familiar technology offers a cure for the catastrophic failure.

Options are limited. Do you insert a stock standard replacement motor – something from the period but a poor substitute without the competition innovations and pedigree – and pretend it is all as it should be? Do you accept that the integrity of the historical object is destroyed, but at least it still drives. Might you surrender, conserve the object and your funds and turn the car into a static museum piece? Or do you trust technology and go where no one has been before?

Remind yourself that old cars were once new. Technology that has long been superseded was back in its day cutting edge. So there is a wonderful poetic symmetry when the most technically advanced engine of a century ago is replicated using the most advanced techniques available today.

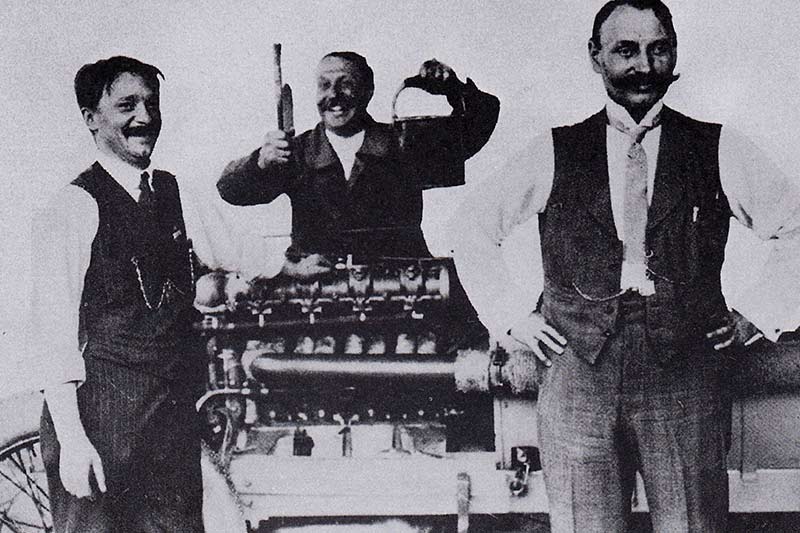

In what is claimed to be a global first application of 3D printing, one of the worlds oldest surviving Grand Prix racing cars has been returned to the road. The 1914 Delage was one of three identical factory entries for the 1914 Grand Prix in Lyon in France. She was only saved from ‘The Great War’ by being exported first to the USA and then eventually many decades ago to Australia. She had been used reliably until – several years ago – a crack developed in the water jacket in the original engine block. Water meets oil.

Now, demonstrating typical Aussie ingenuity and more than a fair dose of engineering flair, a dedicated team of experts has cloned the broken engine block, casting a new one from a sand mould created by a 3D printer.

Nothing this complex has been tried before in the many emerging automotive applications of 3D printing. It is a leap into the future. It means a historic and incredibly valuable car is saved and can race again, using a motor that is in every minute detail totally identical to the broken original.

The Delage resides in suburban Melbourne, but is fettled by Grant Cowie and his team at ‘Up The Creek’ Garage in Castlemaine in Central Victoria, the self proclaimed hot rod capital of Australia.

"In my opinion it is the best car in Australia" says Grant. After various failed attempts at repairing the cracked block with conventional methods, including laser welding, the bold decision was taken to go lateral. "I thought we have to do this differently, a totally new approach" says the transplanted Kiwi who has developed a well deserved reputation as a classic, veteran and vintage car wizard.

Owner Stuart Murdoch placed trust in the team, despite the leap into the unknown with his precious heirloom. "Boldness be my friend" was his guiding emotion as they set to work.

Industrial designer Phil Guilfoyle stepped forward as project manager. His combination of engineering nouse with mastery of emerging technologies leaves him with unique insights into what can today be achieved. "What this technology offers is a solution that is incredibly accurate, non-destructive and quick. It is very cost effective and really suits high-value, low-volume manufacturing".

The original motor was totally stripped, subjected to metallurgical analysis and scanned minutely over every surface, inside and out.

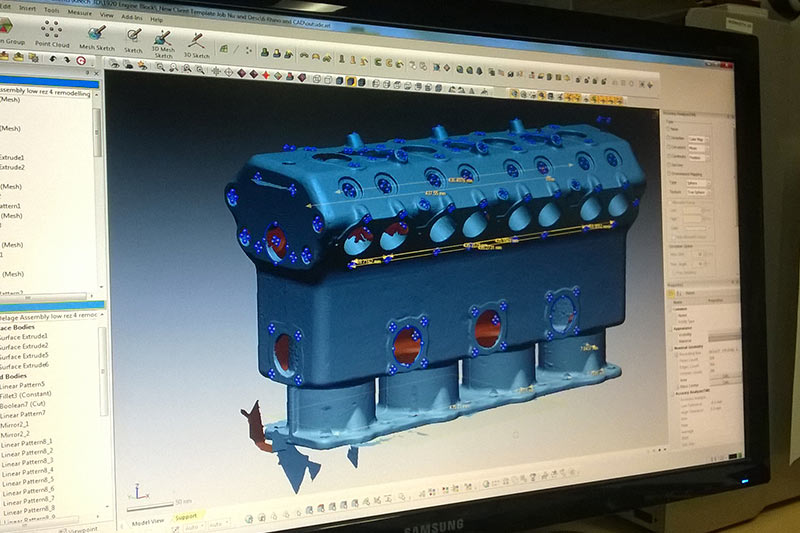

The resulting 3D-scan then became a CAD (Computer-Aided Design) model, appeared on screen and could be adjusted and modified digitally as required. Obviously the fractured metal was repaired, curing on the screen and in the virtual world the damage that proved unrepairable in the real world.

The data was sent to CSIRO who have the only 3D sand printer in the country. Their interest in the project was not commercial but scientific. They want to push the science to its limits and to see if the emerging technology could solve such a complex problem.

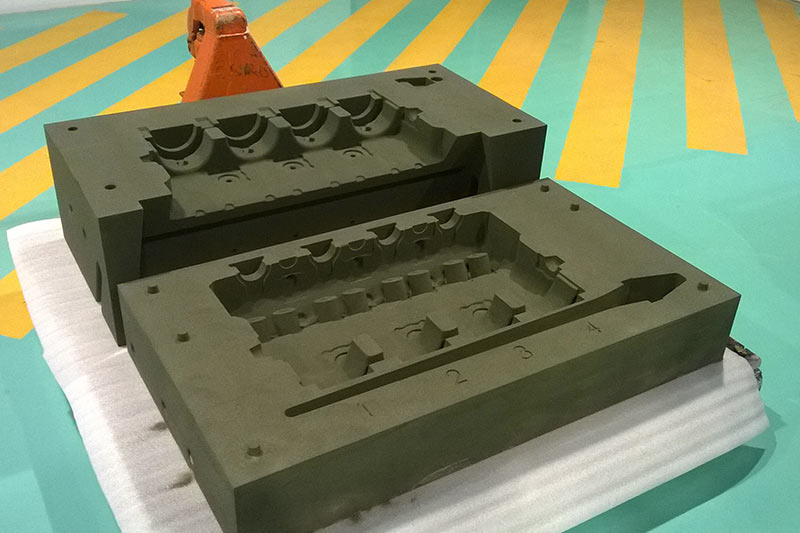

Casting an entire new block from a mould set made by traditional pattern making for this Delage engine block – as done when it was new – would require somewhere in excess of 40 individual wooden patterns to be made, estimated to take thousands of hours and much more than a year. Any adjustments would require similar time frames all over again. The savings from using the computer technology are self evident.

The crew at Keech Australia in Bendigo were given the task of casting the block. The work at the foundry is the only part of the process that is relatively unchanged. Just like in 1914, they still mix and melt the correct formula of metal and pour it into a mould. This step is comparatively quick, but there are fewer and fewer places remaining where it can be done.

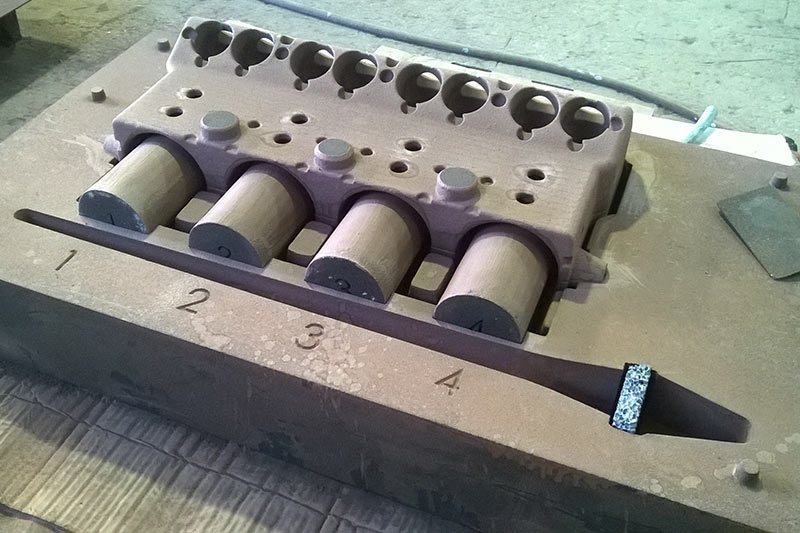

The genius of using laser scanning and 3D printing is not only saving time and money, but also agility. For the Delage, the first new block poured at the foundry was sacrificed and sliced in two. Despite having cost a considerable amount to make, the block was cut into sections to allow an inspection of its innards. Precise measurements of cylinder walls and water jackets proved the wisdom of that decision. Small imperfections requiring internal adjustments can all be attended to on screen, adjusting the CAD model and moving parts of the pattern a thou here and there as needed. Then once satisfied that all is was it ought to be, Phil Guilfoyle simply sent the updated data back to the printer, the CSIRO printed out another sand mould, which in turn was sent to the foundry and an improved block emerged from the sparks.

The final block was in every way identical to the original. All the century-old markings from the Delage factory, every bump, every scratch, even some chisel marks where a bolt required extra clearance and a somewhat brutal method was used to cut the block, all are reproduced exactly. "What has been done is really in the miracle department – it is such a precise copy, it is truly a clone of the original" says a beaming Stuart.

Already, a second project is under way. And Phil Guilfoyle has already been contacted by restorers in Europe going the same route to revive museum quality cars without compromising their integrity.

1914 DELAGE

The Grand Prix Delage Type S was extraordinarily advanced. It had the world's first successful desmodromic 16-valve multi-cylinder engine, copied by Mercedes race cars in the 1950s and in today's Ducati motorcycles. A five speed gearbox – in 1914 – and multi-plate clutch was matched with the then novel innovation of four-wheel cable-operated brakes. The accelerator is in the middle of the pedal set, as was common for the time. The brakes are actuated by a single long-throw lever at the driver's right hand.

The riding mechanic regularly pumps fuel with the dash mounted plunger and hangs on for dear life. Starting requires adjusting the advance and retard on the central steering boss, and the mechanic cranks from the front whilst the driver switches the magneto. This car has had a modern starter motor secretly tucked inside the bell housing, invisible to the naked eye but making the car much more user friendly. She is thought to be capable of still hitting the ton. 100mph not km/h. To the disappointment of the French crowd, Mercedes came first, second and third in the 1914 Lyon Grand Prix.

3D ENGINE PRINTING

1. Thorough scanning of casting is underway.

2. Scale moulds demonstrate the complexity of the task.

3. Trial mould begins to come together.

4. At the foundry and ready to pour.

5. Trial block casting emerges.

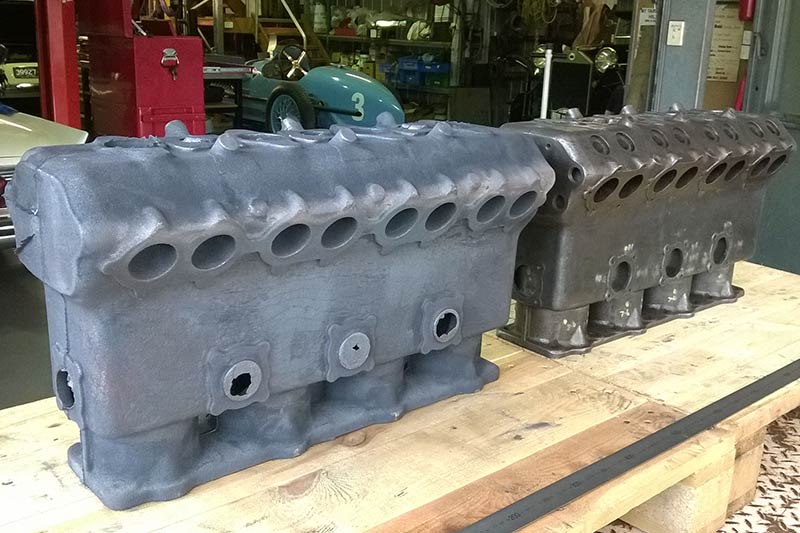

6. Trial casting with original.

7. Production mould takes shape.

8. Production mould is assembled.

9. As good as new – No, make that better than new.

10. All together now, with no bits left over.

11. On the road again.

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)