Restoration tips & tricks - Engine

Part two of our Restoration Tips & Tricks series - let's tackle the engine.

|

|

Restoration tips & tricks - Engine

|

Restoration tips & tricks - Engine

One of the fun things about working on Unique Cars is the build projects we get involved in. Not so long ago, we not only built a couple of V8s, but we gave them away! Along the way we got a great insight into how to go about building a tough and reliable powerplant, and what better place to revisit it than in a muscle car mag? In this case we’re going for one of the most popular project car engines on the planet, a Chev-based 350. These end up in all sorts of cars because they offer good power potential and they’re reasonably compact.

Precision International, which has been involved with the motor trade for the best part of 40 years, supplied the makings of a powerplant that looks like an engine builder’s wish list. That lot was machined and assembled by the Top Torque workshop in Melbourne.

So what have we got? You shouldn’t be surprised that our in-house project manager and bent-eight enthusiast, Uncle Phil, has had a hand in all of this. He figures there are plenty of people out there who could use a small block, and the sales numbers tend to back that up.

Although they supply a huge range of parts for different styles of engine, Matt Wood from Precision says the small block is the company’s second-best selling engine, just nudged out by Ford Clevelands. But hey, the Clevo’s a story for another day. Sean Griffioen, manager of Top Torque, agrees that people can’t seem to get enough of small blocks.

"It’s ridiculous how many 350 Chev engines are around. We’ve built them for anything from Corollas through to HQs and some of your newer boats – we do a lot for boats – they are in absolutely everything," he says.

"They are the most versatile engine around. We do a lot of them. There are lots of add-ons and there are always new products coming out to improve them."

So what did the good folk Precision send us? The basis of the whole plot is a performance four-bolt mains block which, Matt tells us, "has a few modern features to improve reliability [such as] a single piece rear main seal – they’re less prone to leaking."

Dropping in there will be a Scat crankshaft running standard stroke, matched to a set of Scat I-beam rods. "They’re a bronze-fit conrod for a full-floating piston," Matt says, which all "help on the horsepower side of things." Mounted on the rods is a set of 0.020 oversizedHypertec flat-top pistons. Topping off that lot is a tasty looking set of Precision’s own cylinder heads.

Sean, originally a fitter and turner by trade, is clearly a fan, saying they’re half the weight of the stock units and include better, updated porting. Matt reckons they dissipate heat a whole lot better and allow the tuner to run an extra point of compression. "That’s where you get your performance from," he adds.

As for cams, they’ve gone for the biggest profile they can while still keeping it street-friendly and, if possible, enabling the new owner to stick with a standard torque converter. Topping off that lot is the popular 600cfm Holley carburettor. That’s not terribly big, but it’s in keeping with our intention of making this a street-friendly engine. Ignition is by Mallory and Matt is clearly a fan of their well-regarded products.

"It’s basically a set-and-forget system," he says. "They are a good quality unit. There are a lot of eBay sellers out there and sometimes people skimp and put a $100 distributor in an engine and destroy it. The Mallory units are very accurate and that’s pretty important."

Now if you’re thinking that all we have to do from here is bolt together this giant ‘Meccano’ set, you’d be wrong.

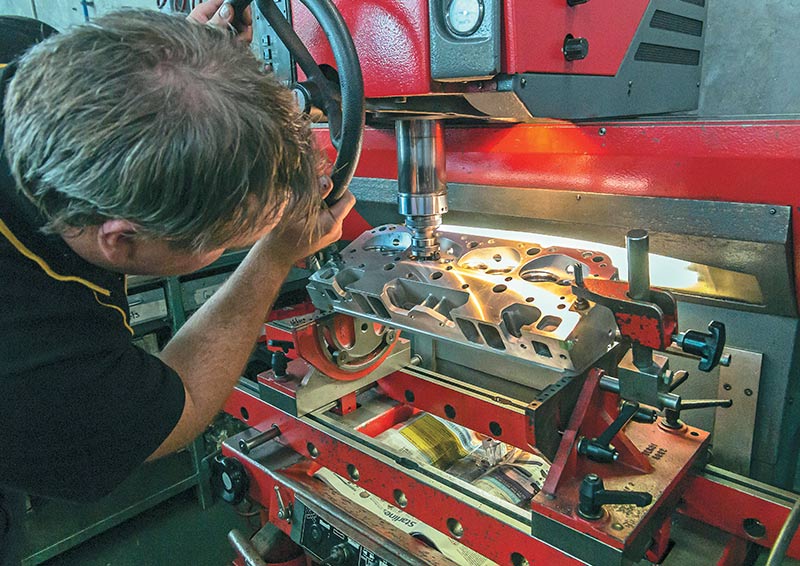

Matt and Sean emphasise the importance of machining key components so you get the most exact fit possible. That way the powerplant has better integrity, will perform better, and actually last longer.

Critical to the whole engine building exercise (and this should really happen even before you start picking parts) is working out what the ‘brief’ for your engine really is.

"Normally a guy comes in with an idea and we’ll throw in a few more," says Sean. "Maybe there are some things he or she hasn’t considered.

"You need to know what the application is and what it’s going to do once it leaves the building. The time frame is anything from three to four days for a standard engine up to three weeks, depending on the amount of machining and what it needs."

Sean says he usually gets the owner to come along during the build.

"We always try to keep the customer heavily involved so, at the end of the day, it becomes their project. Before it all goes together, I feel it’s important for them to come and have a look and see what’s going into it."

Do we have a horsepower target? Not really. Sean points out that 600 horses is achievable if you want to go completely wild, while Matt says 350-400hp is about right for the sort of project we have in mind. That’s more than enough to make any car interesting, without turning it into some high-strung monster to drive.

What’s involved in getting the project off the ground? "So far we have bored and honed the block to the pistons we have got from Precision," explains Sean. "We’ve also surfaced the block and we’ve set up our deck height there.

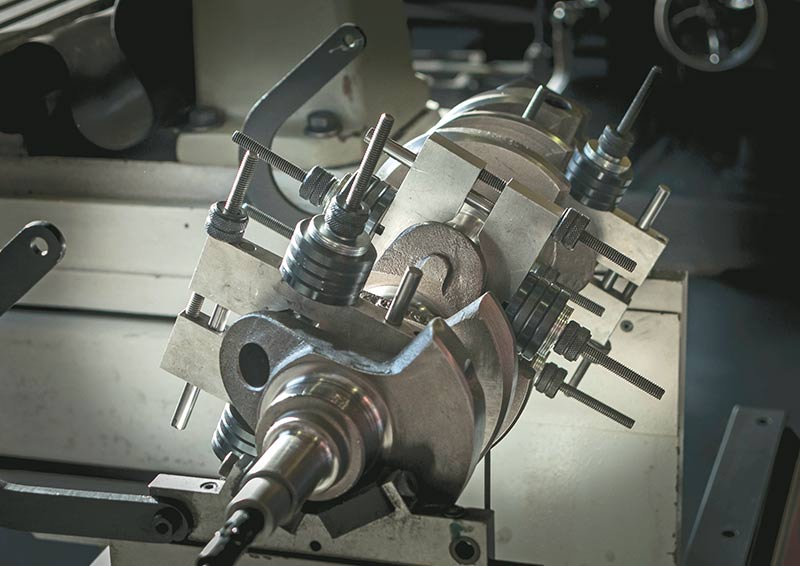

"We have balanced the crankshaft, the conrod and piston assembly as well, so we’re now at a stage where we’re ready to assemble our bottom end.

"The crew has also spent a lot of time on the heads, ensuring the valve seats are spot-on and that all the mating surfaces are perfect.

"The final washing and fitting of cam bearings has yet to be done, but the basic machining is ready to go," adds Sean.

It’s easy to assume that you could just grab all this stuff and bolt it together, and that is physically possible. So why go to all this additional trouble?

"It’s imperative to make sure everything works with its fellow component," continues Sean. "It’s important the pistons have the correct clearance, that the conrods have clearance to the block, that their tunnels are the right size. It’s important the reciprocating assemblies are the right weight in relation to the crankshaft and the crankshaft itself is properly balanced.

"That all adds to the engine’s longevity and power. Once it’s all built, it makes for a much nicer package and a much more reliable engine." Does this qualify as blueprinting?

Blueprinting, says Sean, is taking the engine to its exact tolerances, so every clearance is exactly as the manufacturer intended it to be. All the bearing clearances are right, all the piston clearances are right, the ring end gaps are correct – the list goes on. It’s one of those jobs where you need experience, a feel for what you’re doing and what seems like an infinite amount of patience.

According to Sean this experience represents a huge part of the cost of employing an engine reconditioner. "It’s the time taken for someone to go and check every bearing, journal and gap and make sure it’s all right."

Somewhat ironically, you can in fact end up with a powerplant that follows the blueprints more accurately than one straight out of the original factory.

"Every engine built by a professional engine reconditioner is effectively blueprinted," he says. "We check those tolerances, make sure they’re correct and make sure the thing’s got good oil pressure and that it’s not going to have a problem."

Okay, so we’re being told all this work will result in a stronger and longer lasting engine. But by how much? Sean reckons that’s impossible to quantify. "But, when the rod and piston mass is the same as the counterweight on the crankshaft you’ve got good weight balance, which means you get good, even bearing wear on all your journals. It avoids one bearing failing before another one and just gives it a nice even load across the whole crank."

"It absolutely makes a difference to driveability," he adds. "It makes an engine a lot smoother, a lot crisper. I’ve had customers say many a time that they were glad they spent the money to get it balanced. It just makes the engine so much nicer to drive. It’s better at idle and high revs, too.

"It’s at high revs where balancing is particularly important, when it’s really singing," Sean concludes.

So the moral to the rebuild story from Sean’s point of view is to get it done properly the first time around. He reckons scrimping on this stage is a false economy, because the extra spent is more than repaid when you finally drive it.

Let’s move on to assembly. "We put the bearings in the block and the caps," explains Sean. "We check all the clearances to the crankshaft and make sure they’re all correct and don’t need adjusting. We fit the rear main seal, put our assembly lube in there and drop our crank in. We put our main caps on and tension them. We don’t shim crankshafts anymore; if there’s an issue we either line-hone or grind the crankshaft to suit.

"Next up are the piston ring gaps. We put them in the bores, check our gaps, and put the rings on the pistons." Why so much emphasis on the ring gaps? "The ring expands in the cylinder as the engine heats up. If the ring gap is not correct the ring can butt-up and seize in the bore. On the other side if the gap is too high, that’s when you get blow-by into the crankcase, oil leaks and all sorts of horrible issues."

Part of getting that right is accurate boring equipment, which Top Torque has in-house. Are consistent bores important? "Absolutely, it’s critical for any motor. We always make sure our tolerances are the same regardless of whether it’s an early engine or a later, technically-advanced performance engine.

"Correct tolerances make the engine a better package and you’re giving it the best shot at life that you can. If it’s got excessive clearances, it’s already half worn-out."

Fitting up the piston and rod package is the next step and here, a lot of prep work has been done. "We balance everything – pistons, conrods, the crankshaft, our flex plate and our harmonic balancer. This doesn’t give any more power, but it makes the engine run smoother and makes it wear evenly, so you’re not getting one bearing copping a harder time than another.

"We put our camshaft in, set up the timing and then dial it in so we get as much out of it as we can. Essentially we’re checking to make sure it’s right and adjust with the gear set to the specs provided by the maker," says Sean.

"Your engine will still run if it’s not quite right, but by the same token you’re not getting the absolute best out of it." The model we’ve gone for is a middle-of-the-road grind, aimed at a lively end result nearing the 350-400bhp mark.

"It’s still a fairly street-able engine," Sean says. "Nothing that’s too wild or going to shake the engine out of the car."

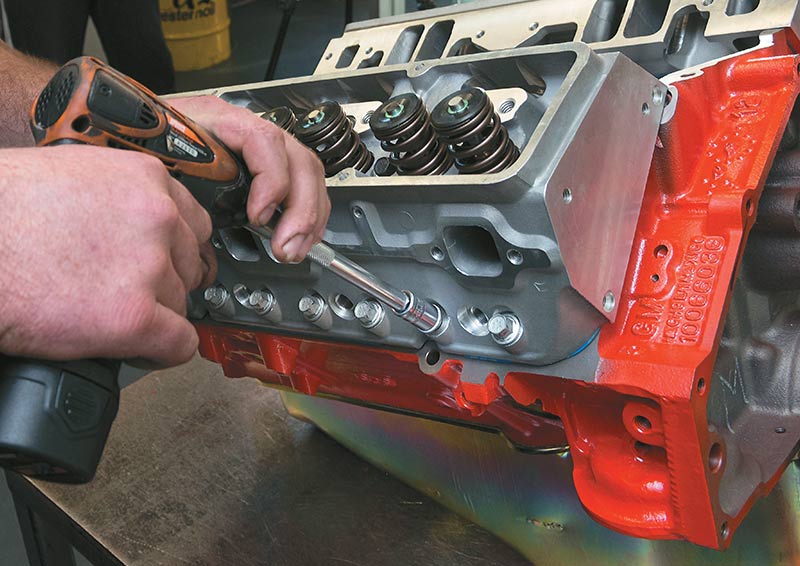

Across the bench, the new alloy cylinder heads are ready to go. It seems like a shame to fit them, as they’re beautifully finished. "We fit the gaskets, lube the bolts and bolt them down to the correct torque," explains Sean.

"Once the heads are down we set up the rockers and check the rocker ratio and rocker swipe to make sure it’s not hammering out a valve."

Essentially Sean and his crew are ensuring the rocker is hitting the valve ‘square’ to avoid early wear such as worn guides.

"We mark the top of the rocker and turn the engine over, making sure the rocker is sitting centrally on the valve, so it’s not pulling it out of or into the engine. That stops the guides from wearing out and makes sure it’s actuating properly."

By this stage we’re on the home stretch and the plot has taken a recognisable shape. Now we’re gathering up the tinware, which Sean happily describes as "all the nice shiny parts such as the rocker covers, timing cover and sump. We dress the engine, make it look smart".

Capping off the powerplant is the carburettor. All too often we hear of people fitting giant carbs to their engines, wrongly assuming that shoving more fuel in with a too-big carby always means more punch. It ain’t necessarily so.

"We’ve gone for a Holley 650," says Sean, "which is a good-sized carb for the power the engine will produce. It still leaves a little flexibility if someone wants to go a little further with the performance."

It seems simple enough when you watch the experts at work, but how about an engine assembly ‘top tip’ for us mere mortals?

"Cleanliness is the number one priority when you’re assembling an engine. Everything must be cleaned, cleaned and cleaned again," states Mr G.

"Of the time we spend assembling an engine, probably half is spent on cleaning to make sure everything is absolutely spotless."

See all three parts of this story:

Part 1: Restoration tips & tricks - body

Part 3: Restoration tips & tricks - finishing it off

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)