Ferrari Testarossa replica review

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

Ferrari Testarossa replica

|

|

Ferrari Testarossa replica

|

|

|

Ferrari Testarossa replica

|

|

|

Ferrari Testarossa replica

|

|

|

Ferrari Testarossa replica

|

|

|

Ferrari Testarossa replica

|

|

|

Ferrari Testarossa replica

|

|

|

Ferrari Testarossa replica

|

|

|

Ferrari Testarossa replica

|

|

|

Ferrari Testarossa replica

|

|

|

Ferrari Testarossa replica

|

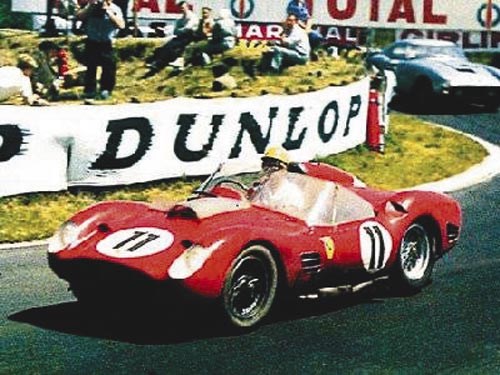

An Australian company recreates Ferrari’s legendary TR250 but forget thoughts of feral Aussie brumbies – these mechanical equines are superior to Enzo’s original Italian stallions

|

|

Ferrari Testarossa replica

|

First published Unique Cars magazine, issue #242 (Dec, 2004-Jan, 2005)

Ferrari Testarossa replica

The cantankerous burbling of the V12 engine turns to a guttural howl as the corner apex is cleared and the nose of the Ferrari points to open straight space. Six downdraft carburettor throats pulse in unison, spitting mist and gurgling as each strains for its share of air.

It is a noise symbolic of everything great about Ferrari’s post-war domination of Grand Prix racing. A noise guaranteed to send shivers up the spine of any hardcore racing enthusiast. We were in the presence of greatness; standing in the shadow of Finch Restorations’ hand-crafted 1959 TR250 Ferrari Testarossa replica.

Get any thoughts of wood glue, Tek screws and rough glass panels out of your mind now, and compare this replica to the bespoke creations from fabled coachbuilders of yore.

Perfect in every detail, from the headlight covers through to the hand crafted aluminium body, this TR250 is possibly an even better example of the breed than Ferrari was able to produce itself. A growing number of international clients agree, with the Finch Testarossa being widely lauded as the finest replica of its type in the world.

"This car is actually based on TR250 chassis number 672," explained Finch Restorations owner Graham Crowley. "Which also happened to be number 768… before it was written off."

It is this melding and sharing of partial car fragments (generally after massive racing accidents) that has seen the current world population of TR250s rise from an initial build of three cars through to more than 30 registered examples.

"It was quite possible to have a damaged 1958 pontoon (fender body), which could go back to the factory, be repaired and then rebadged as an entirely different model and chassis number," Graham said.

All of which makes the work of Graham and his company extremely time consuming and tricky to say the least.

"A customer comes to us with an order for one of these cars and a chassis number of an existing TR250 upon which they want their car based," he said. "We then spend an enormous amount of time researching every tiny detail of the car in question, and recreate it exactly. The trick here is that no two TR250s were ever built the same."

Certainly we could pick no fault in the Finch TR250 sitting before us in the car park. With just under 2000 man-hours being put into each vehicle at the Finch workshop, the process is a slow one.

Still, Crowley is critical of his own work. With the car we photographed being shipped to a customer in Pennsylvania, Graham still reckoned there was room for improvement.

For example, he points towards the V12 nestled in the bonnet.

"See the carburettors? They aren’t the right unit, as this car is being fuel injected the moment the customer picks it up in the US. The right parts are 38DNFs, which are almost impossible to get and cost well over $10,000. It would have been false economy to fit them to this engine simply for transport.

"Then there are the rims. As this car will be raced in the US, a special set of custom, high-strength Dayton rims is being fitted by the customer, so once more these rims are there simply for the shipping process."

It takes an expert eye to pick these gaps in the TR250 makeup, but that is exactly what Graham has.

The process of putting together a TR250 replica is every bit as interesting as the end result. "People come to us with a basic request," Graham explained.

"At the moment we are dealing with a customer in South Africa who wants a Finch TR250 and his wish-list is a simple one. He wants the most accurate factory-style car. So we will go about and source every single correct part, from the carbies through to the factory rims."

These cars are not cheap and Graham is adamant he will not make any concessions to the authenticity of his products.

"In most instances," he said "we need to strip down a $60,000 second-hand car to get the running gear and detail parts we require for our replicas."

Key to the quality of the Finch TR250 is the dimensionally correct structure of the aluminium bodywork.

"We originally got ourselves a scale model of the vehicle and then had it placed into a machine that built a ‘reference cloud’ of the body’s critical dimensions. It hits something like 1000 points-per-inch, and makes a 3D rendered model of the car. From there it is clothed and coloured-in using CAD. The result is a series of ‘stations’ that we generate on the computer, which can then be crafted in wood by our shipwright in true 1:1 scale."

Three different aluminium forming processes are used by Finch to get the curves and shapes of the voluptuous Ferrari body exact and then each and every part is checked on the wooden computer-generated body-buck for correct shape and form. None of the guard cutting (for wheel clearance) or panel joining is carried out at this stage, with the final assembly of the body happening on the completed chassis.

The chassis is constructed in a separate area of the workshop, with its manufacture coinciding with that of the body. A large jig has been constructed upon which the space-frame chassis of the Finch TR250 is fabricated. Once more it is a dimensionally correct piece and matches the tolerances of the hand formed bodywork perfectly.

Watching individual sections of the construction process gives even the casual observer some insight into the time consuming nature of the business.

Powering the pictured example is a 4.4-litre twin cam Ferrari V12. There are several engine options from the era, though, with either a 3.0-litre or a 4.0-litre Ferrari V12 also able to be substituted. Original transmission parts though are almost impossible to come by.

"We took the decision to use the six-speed Getrag transmission from a twin-turbo Supra," Graham said, "and then combined it with the complete rear-end and differential assembly from a Subaru WRX."

These parts are well able to handle the 276kW output of the Ferrari engine and give the replicas superior driveability to the original driveline.

The result of the monstrous research, engineering and fabrication effort is a turn-key Finch replica similar to the one you see here, but the important question still needs to be answered, "What’s it drive like?" Graham laughed when he recounts his experiences.

"You have to realise that these cars are pretty light compared to anything available today, weighing in at about 1200kg (depending on options). With 370hp on tap, and really sharp throttle response from the big V12, they are a true 160mph (255km/h) motor car, and well capable of matching it with modern high-performance offerings."

Graham realises, though, that with expensive (and often-difficult) genuine Ferrari parts supply, public demand for his Finch TR250 will be small and confined to mainly wealthy overseas clients.

Making a more affordable and accessible version of the car is therefore high on the priority list, and plans are well underway to produce a locally available and road-registrable version of the Finch TR250, powered by an LS1 Gen III V8 engine and mated to the six-speed T56 Tremec transmission.

Sacrilege some may claim, but the irresistible nature of eight ram tubes poking into the Perspex bonnet bulge, the lumpy idle of a mildly-tuned V8 and the 335kW-plus of power delivery will be more than enough for a select handful to make the decision and enjoy the rewards that only a truly hand-built car can offer.

RACING ROSSA

The name Testarossa (literally translated to ‘redhead’) embodies the best of Ferrari’s rich racing pedigree. With V12 aluminium engines designed by the legendary Gioacchino Colombo, the TR250 effectively out-powered its competition of the era and displayed a reliability that is synonymous with modern Ferrari Formula One efforts.

Heading up the Ferrari trophy case is a trio of world championships attained with the TR250 in 1958, 1960, and 1961. In all, counting in the endurance race wins and other international victories, the Testarossa won a total of 13 major titles, which makes it one of the most important and influential racing cars of its era. The car’s only failing was poor aerodynamics, which limited top speed; something that was later fixed with the ‘cleaner’ 250 GTO body shape.

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)