Points-Based Ignition Systems - Workshop Tips

|

Is there any point in having points? Not if you can avoid it

From the archives: Unique Cars #295, Feb/Mar 2009

Ignition systems

There can be a lot of reasons an older car will run badly, but if it’s equipped with an original points-based ignition system you may not have to look much further to find the cause.

Any OE distributor ignition system that’s still functioning on an older car is almost certainly going to be performing poorly. This is likely to be the case even if it’s been serviced regularly because things other than worn points, rotor buttons and caps can contribute to poor running. Worn bushes, for example, will have a detrimental effect. The biggest hindrance to ignition performance in early model cars is the design – it’s simply outdated technology.

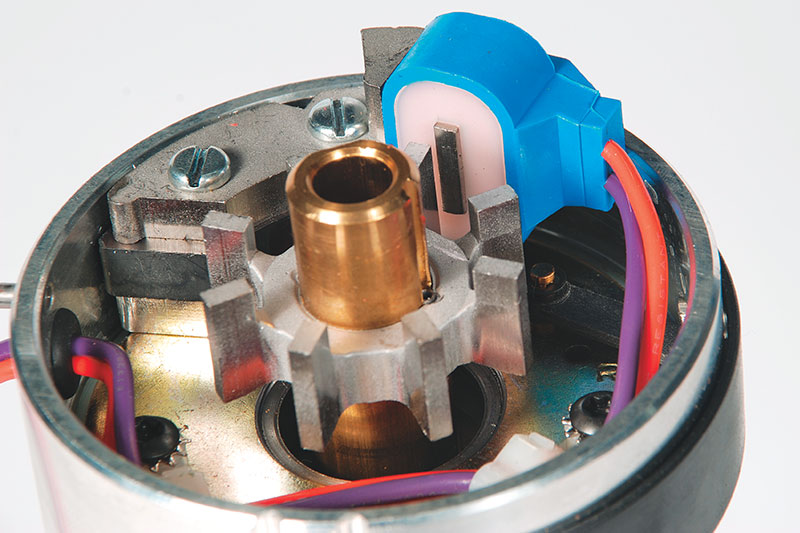

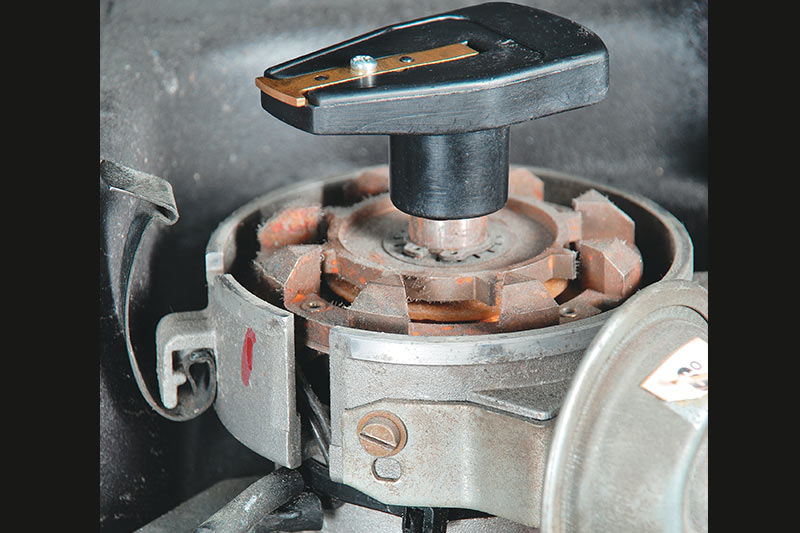

You can see in this dual points system that one set of points is open while the other is closed

You can see in this dual points system that one set of points is open while the other is closed

An ignition system works by increasing the basic system voltage of the car to a value capable of forcing a spark to jump the electrode gap in a spark plug. This stepping up of the basic 12 volts from the battery occurs in the coil. Each coil has a primary and a secondary winding. The primary side consists of a couple of hundred windings of wire and is supplied with 12 volts from the electrical system through the points (in a points based system). As current flows through the primary winding it causes a magnetic field to extend out and envelope the secondary windings, which may number as many as 2000 turns of much thinner wire.

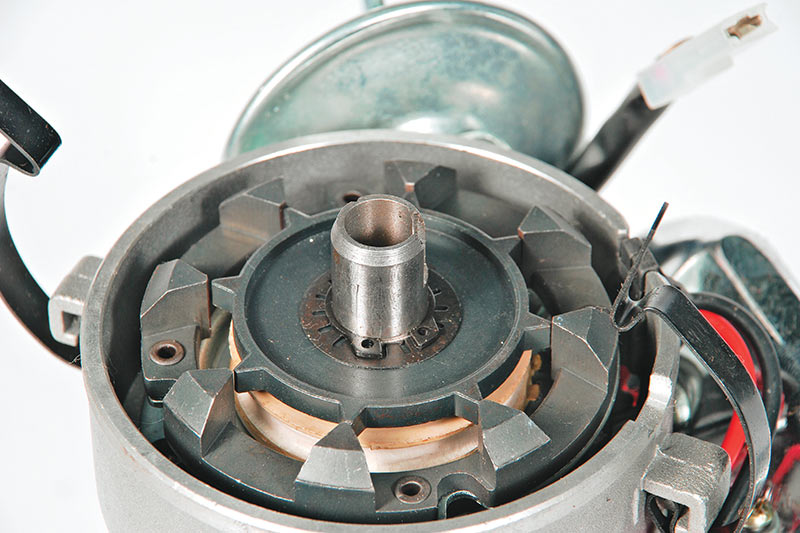

A magnetically triggered system with just one sensing coil

A magnetically triggered system with just one sensing coil

GET TO THE POINT

When the rotating cam within the distributor pushes the points open, the 12 volt supply to the primary windings is cut and the magnetic field collapses. As it does so, it falls through the secondary windings and creates voltage within them. Because there are so many more secondary windings than primaries, the voltage increase from the original 12 volts is enormous.

The more rapidly the current to the primary winding is cut, the greater the voltage induced in the secondary windings will be and the stronger the resultant spark will be. Unfortunately, using points is one of the slowest ways to cut the primary current. In fact, it’s so slow that current continues to arc between the points as they’re first opened. That’s why they become pitted and need filing and gapping as part of regular servicing.

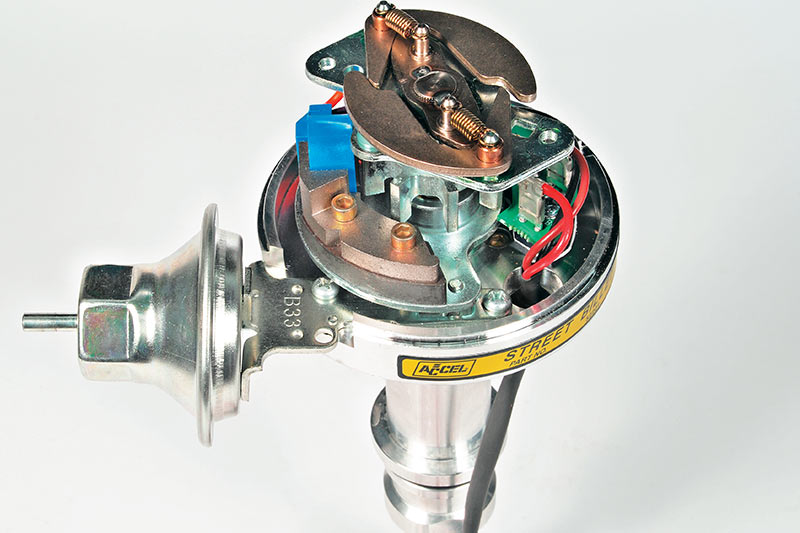

An HEI based aftermarket system. The multiple magnetic points create a stronger signal

An HEI based aftermarket system. The multiple magnetic points create a stronger signal

If current to the primary winding is supplied for long enough, the resultant magnetic field reaches a maximum value. At this point the coil is said to be fully saturated. So, the longer a coil is charged before current to the primary is cut, the closer the coil will be to fully saturated. Because points are pushed open mechanically by a cam, the number of degrees of distributor shaft rotation during which no current is supplied to the primary winding is quite high. This limits saturation, which reduces secondary voltage and limits the strength of the spark. Dual point ignitions were introduced to improve this problem.

Changing the spring on the weights alters the advance characteristics of a distributor. The vacuum canister also advances the timing

Changing the spring on the weights alters the advance characteristics of a distributor. The vacuum canister also advances the timing

A dual point distributor has two sets of points and current to the primary winding can pass through either of them. The points are staggered slightly in relation to each other which means that one set begins open first, yet current to the primary is only cut when both sets of points are open together. So, it’s the opening of the trailing set of points that cuts current to the primary. However, because the leading points open before the trailing ones, they also close before the trailing set. This allows current to be resupplied to the primary winding before the trailing points have closed. Effectively, this increases what’s known as the dwell angle, which is the number of degrees of distributor rotation for which current is supplied to the primary winding.

The flat plates on the caps of these IC&E distributors are designed to clamp the leads in place

The flat plates on the caps of these IC&E distributors are designed to clamp the leads in place

MAKE THE SWITCH

Brand new dual point systems are still available and they are an improvement over single point systems. However, they still suffer the problem of slow switching. And because points are operated by a cam within the distributor, at high engine speeds they can be flicked open with such force that they cease following the cam profile. This means that they may still be partially open by the time the next lobe rotates around into contact with them. This causes all sorts of problems. Stronger return springs help but they introduce other difficulties. The bottom line is that points based systems of any type simply don’t measure up to modern systems.

Many new distributors come with supplementary electronics boxes that contain a number of advance curves and rev limiters

Many new distributors come with supplementary electronics boxes that contain a number of advance curves and rev limiters

More modern distributors use transistors to switch current to the primary windings. These are much, much faster, resulting in more efficient switching and increased dwell angles. The voltage required to turn a transistor on and off is much lower than the main voltage it’s capable of controlling. This introduces a number of options for producing the voltage needed for the triggering signal.

Magnetism is one of the most common methods of generating the triggering signal in a modern distributor.

Care is needed in choosing a coil. Not all of them are compatible with all systems. The safest way is to use the coil recommended for whatever system you buy

Care is needed in choosing a coil. Not all of them are compatible with all systems. The safest way is to use the coil recommended for whatever system you buy

A number of different magnetic triggering systems are used but they all have a number of components in common. Each has a permanent magnet and sensing coil that generates a voltage when the magnetic field changes, and a toothed trigger wheel of some sort that passes close to the magnet/coil assembly as it rotates. The trigger has as many teeth as there are cylinders in the engine and each time one of them passes close to the magnet, a voltage occurs in the sensing coil which signals the transistor to cut power to the primary winding in the ignition coil. The faster the trigger wheel is turned, the stronger the signal voltage will be.

Local company IC&E started out modifying OE HEI systems but now almost everything the company sells is specially manufactured, including coils

Local company IC&E started out modifying OE HEI systems but now almost everything the company sells is specially manufactured, including coils

RESISTANCE IS FUTILE

The Bosch HEI system is quite possibly the ultimate refinement of the magnetic distributor. The time taken for a standard (non HEI) coil to become saturated is increased by the fact that it has internal resistance to changes in current flow. This is known as inductance. Reducing the resistance of the primary winding reduces the time taken to achieve saturation but increases current flow severely, which introduces other problems. In an HEI system the resistance of the primary is much lower but excessive current is avoided by limiting the charge time to about a fifth of that for a standard coil. Consequently, HEI coils never achieve full saturation.

To reduce energy losses, Delco style distributors have the coil on the cap like this. The coil output passes directly into the rotor button

To reduce energy losses, Delco style distributors have the coil on the cap like this. The coil output passes directly into the rotor button

However because of the low resistance, enough current flows through the primary to achieve the necessary voltage increase in the secondary winding, despite the reduced charge time. Many aftermarket distributor upgrades are built around HEI components.

A Hall Effect sensor also uses magnetism but operates on a somewhat different principle. Rather than directly generating a signal voltage in a coil, a Hall Effect mechanism utilizes tangs on a rotating plate to deflect a magnetic field. The advantage of this type of sensor is that it produces a constant voltage right across the rev range, so there are no problems at idle. Like Hall Effect devices, optical sensors also generate constant voltage signals across the entire rev range.

High quality leads have elaborate structures to pass current adequately while having enough resistance to reduce radio interference

High quality leads have elaborate structures to pass current adequately while having enough resistance to reduce radio interference

The good thing about a distributor upgrade is that it’s quick and easy. You simply unbolt and remove your original unit, drop the replacement in, fit the leads and set your timing. The increase in performance over an old standard system can be one of the most dramatic improvements you’ll ever see in a car. Not all distributor upgrades are as self-contained. Some require the fitting of other components along with the distributor.

ADVANCING THE CAUSE

Different operating conditions in an engine call for different spark timing. In older style points systems and, in some electronic systems, alterations to spark timing are effected by weights that move outward due to inertia and progressively pull the triggering system into a more advanced position as engine speed increases.

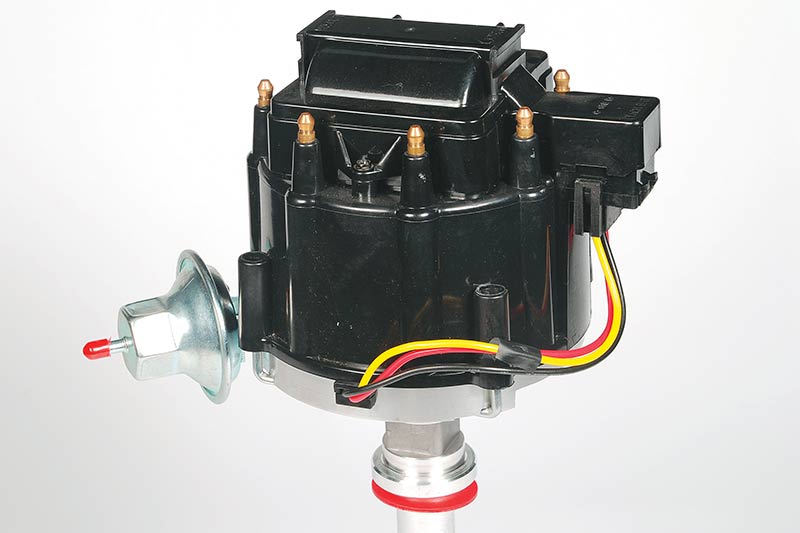

VPW is manufacturing a range of HEI based distributors for Chevs, Holdens, Fords and Chryslers

VPW is manufacturing a range of HEI based distributors for Chevs, Holdens, Fords and Chryslers

During cruising and light load conditions, mixtures are lean. Such mixtures are harder to burn so, again, an advanced spark is needed. Of course there isn’t enough engine speed for the weights in the centrifugal advance mechanism to work. Under these conditions a small vacuum canister connected to the reduced pressure in the inlet manifold pulls the triggering mechanism into the advanced state required. The overall changes to ignition timing throughout the operating range of an engine are collectively known as the advance curve.

The advance curve in some ignition systems is altered electronically. The solid state circuitry that controls this may be attached to the distributor itself as it is in some HEI based systems. In these cases, changing the distributor alone constitutes an ignition system upgrade (apart from plugs, leads, etc).

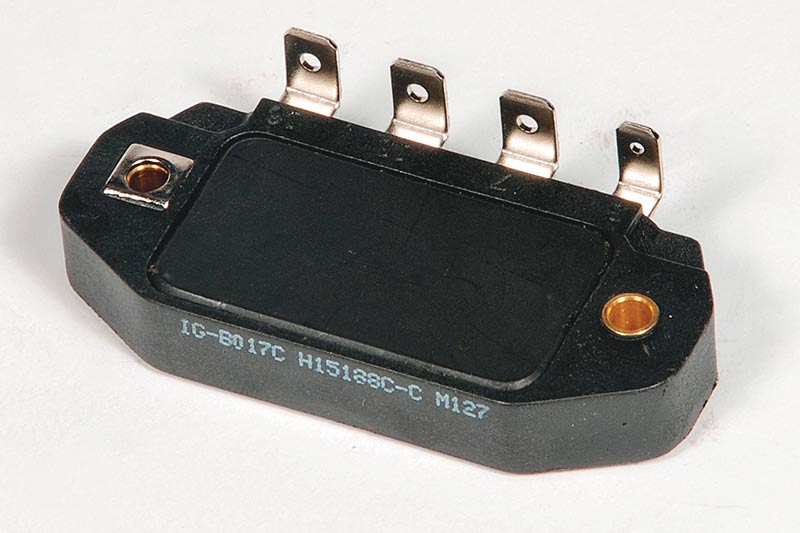

This is the module from an HEI system. It controls the advance curve for the distributor

This is the module from an HEI system. It controls the advance curve for the distributor

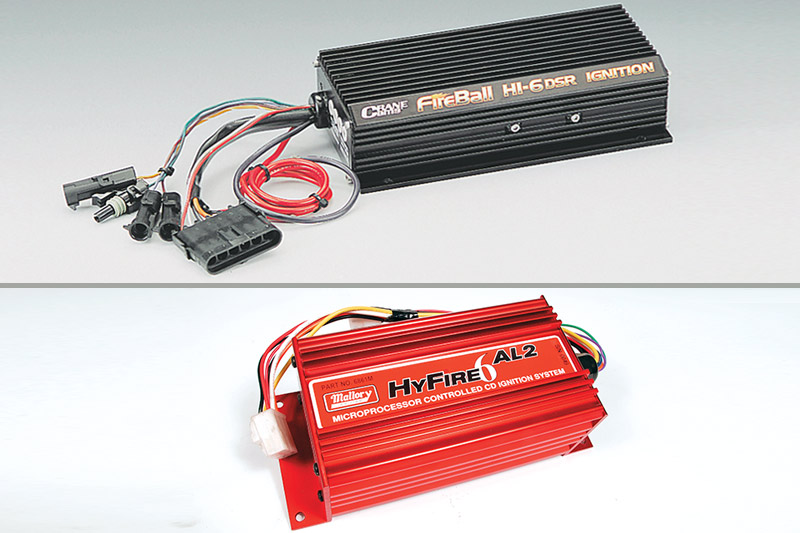

In many newer systems the electronics that control the advance curve have migrated into separate boxes that have to be fitted along with upgraded distributors.

Such systems might offer a number of different advance curves and also feature things like adjustable rev limiters. These are slightly more complicated to fit but the extra options they offer make this worthwhile.

Another type of ignition system characterized by an external box of electronics is the CDI (Capacitive Discharge Ignition) system.

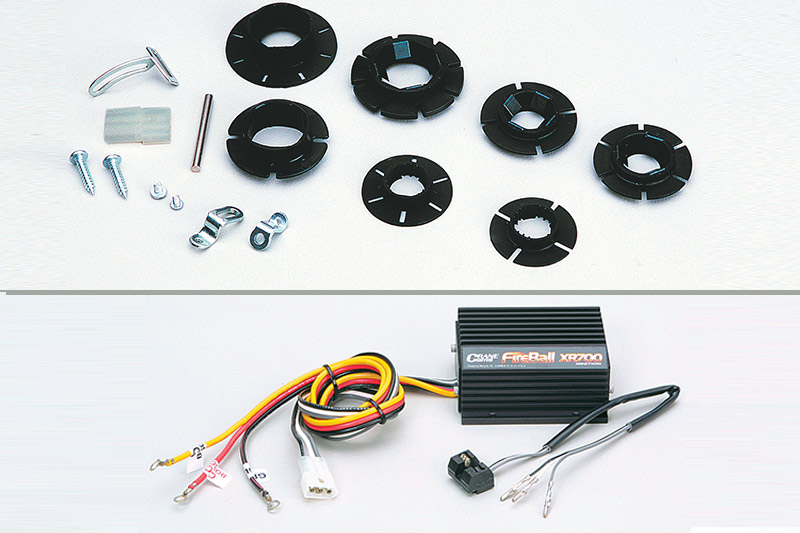

Kits are available to convert points-based distributors to electronic versions. This can be economical and can be a good solution for those wanting to retain authentic looks yet still improve performance

Kits are available to convert points-based distributors to electronic versions. This can be economical and can be a good solution for those wanting to retain authentic looks yet still improve performance

A CDI system still has a coil but it isn’t charged by the 12 volt system. Rather, it utilizes capacitors to store a charge which is then passed into the primary winding of the coil. The thing is, capacitors can be charged and discharged extremely rapidly. This characteristic creates highly intense sparks of very quick duration. In fact, at low engine speeds multiple sparks occur.

A CDI ignition system will create a strong spark under the most severe conditions in a cylinder, which is why they’re popular in race applications. However, there are street versions available which are also very popular.

Optical conversion kits are also available

Optical conversion kits are also available

Well, that’s a basic overview of upgrade options for your distributor/ignition system. You’ll find plenty more interesting reading at iceignition.com, holley.com,

mrgasket.com, malloryracing.com, msd.com and vpw.com.au.

Aftermarket manufacturers like Crane, Mallory, and Accel offer CDI systems for street and track

Aftermarket manufacturers like Crane, Mallory, and Accel offer CDI systems for street and track

FITTING A DISTRIBUTOR

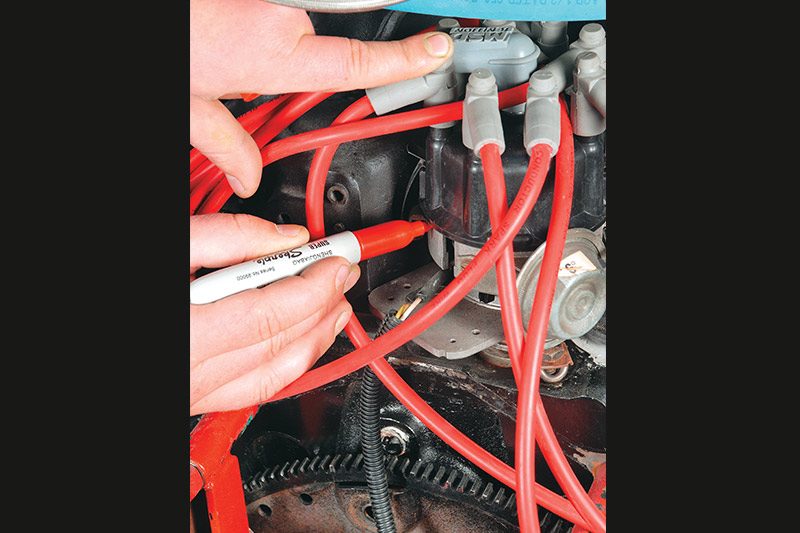

1. The first thing you have to do is set your number one cylinder to TDC on the firing stroke. Find the number one plug lead, trace it back to the distributor and place a mark on the body of the distributor under that terminal.

2. Turn your engine over until the timing mark on your harmonic balancer indicates TDC. If the rotor button is pointing to your mark you’re at TDC on the firing stroke. If not, you’re at TDC on overlap with the valves open. If that’s the case, turn the engine to TDC once more and the button should line up with the mark.

3. You may find that when your distributor drops into place you may not have enough space to turn the body to set your initial advance. If this is the case, lift the distributor out while holding the body and shaft in position with each other, turn them one tooth in the appropriate direction and reinsert the distributor as shown.

4. This is easy in a Holden, however with Fords, Chevs, Chryslers and other cars the distributor shaft also drives the oil pump directly. Therefore, the pump drive shaft has to mate with the drive slot or hex on the bottom of the shaft. If it doesn’t line up, you won’t be able to seat the distributor properly. If this is so, stick a screwdriver or small socket on an extension onto the top of the pump shaft and turn it to match the orientation of the distributor shaft.

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)