Guide to Basic Vehicle Dynamics and Underpinnings

|

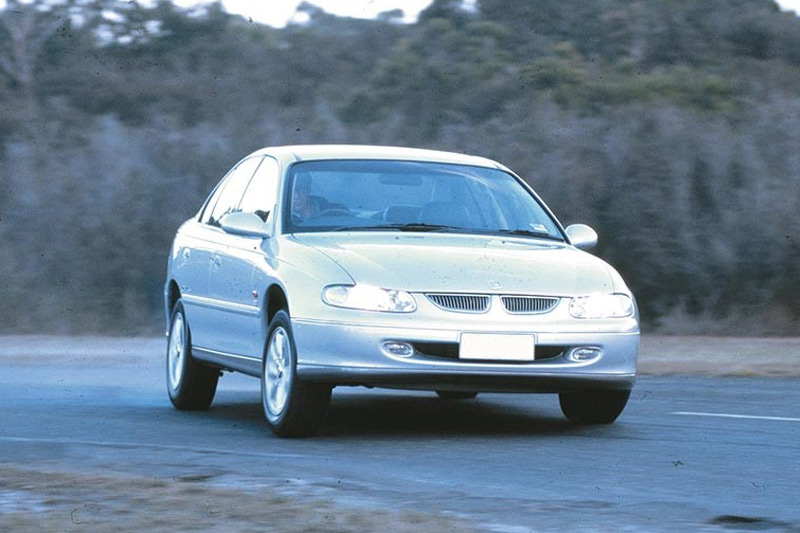

Baffled by the underpinnings of your beast? Here's a guide

First published in Unique Cars #293, Dec 2008

Originally, suspension was all about comfort. In the earliest cars no one was thinking about handling, it was all about minimizing passenger discomfort. It still is, but as cars developed it was realized they could actually go faster if suspension was improved. Manufacturers have been trying to strike a balance between handling and comfort ever since.

These days, they do an extremely good job, although there’s always room for improvement. Why? Because more often than not, handling and comfort are inversely proportional – more of one usually means less of the other.

A few decades ago, manufacturers weren’t so good at balancing handling and comfort. Of course most classic cars are at least that old, so a great deal of improvement is possible for these models. In fact, the suspension in these cars is so bad by modern standards that practically anything you do will be a positive step. We can’t explain everything about suspension here but we can clarify the basics for you. Basic vehicle dynamics is as good a place as any to start.

SLIPPING AWAY

In a cornering car, inertial forces act to create sideways stretch in a tyre. This means that although a wheel is pointed at a particular angle, it will actually ‘sidestep’ and travel through a slightly wider arc. The difference between the direction in which a wheel is pointed and the direction in which it actually travels is known as the slip angle.

When the slip angle at the front of a car is greater than the rear slip angle, the front of the car will follow a wider arc. A car in this state is said to be understeering, or ‘pushing’. That is, it’s not turning as sharply as the wheels are pointed. Conversely, when the rear slip angle exceeds the front slip angle, it’s the rear of the car that follows a wider arc than that defined by the direction of the wheels. This is oversteer.

At factory settings, most rear wheel drive cars oversteer while most front wheel drive cars understeer. In general, one of the main aims of suspension tuning is to get both ends of a car to follow the same curve. This is known as neutral steering.

All forces are transmitted more effectively through firm connections. So, increasing the firmness of suspension components at either end of a car will cause more force to be applied to that end of the car and increase the slip angle.

An anti-roll bar increases the suspension stiffness at the end of the car to which it’s fitted; increasing the diameter of the bar increases the effect. One very common suspension modification is to fit a larger diameter anti-roll bar to the front of a RWD car. This transfers some of the force that was acting at the rear wheels to the front wheels. In effect, it reduces oversteer.

Anti-roll bars are unique in that they only work during cornering. When a car is travelling in a straight line they simply pivot up and down in their mounts without effect as the suspension moves. They’re one of the few stiffening modifications that have little or no effect on comfort during straight line driving.

PLASTIC FANTASTIC

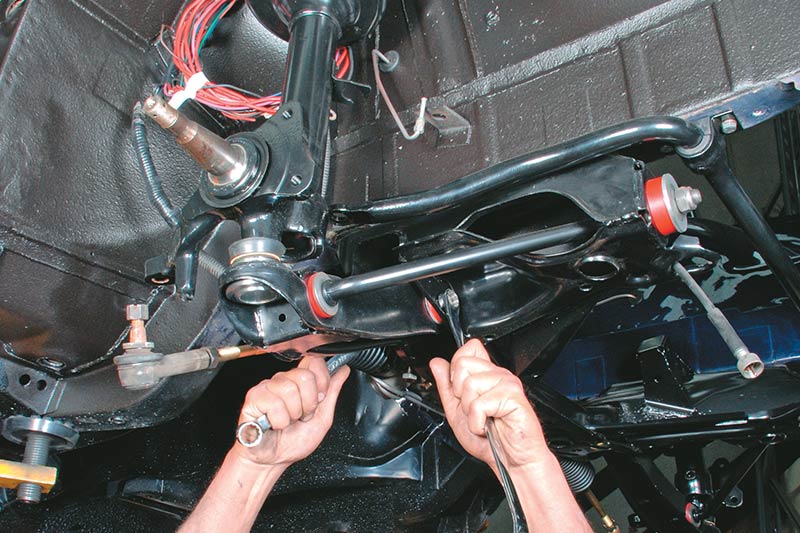

Notwithstanding basic design inadequacies, another reason many old cars have such poor suspension is because components like rubber bushes have simply worn out. For instance, rubber cracks, perishes and often falls out resulting in loose, sloppy suspension components. The choice is to refit rubber bushes or to fit aftermarket replacements made from urethane. Urethane is generally the better choice, but not in all cases.

We spoke with Nathan Williams from Advantage Suspension in Melbourne. Over the years Nathan has tuned some of the fastest track and street cars around. In his opinion, urethane is a really good idea in many places in a suspension system, but there are a few places where rubber is still the better choice. In general, the larger the rubber bush, the more compliance it will have. So, replacing big bushes with urethane is a good idea. However, bushes need to have some ‘give’. When a bush is small and thin, a urethane version may not have enough compliance to work properly. In this case, it could be better to stick with a rubber replacement.

An older style live differential (solid, not IRS) is a good example. During cornering and at other times one side of the diff needs to rise higher than the other in relation to the body. It’s compliance in the bushes that allows this to occur. If the bushes connecting the axle tubes to the lower trailing arms are too stiff, the assembly may bind in operation resulting in less than optimal handling and slower times. Nathan has tested this on many cars at the track. His conclusion? Rubber allows more compliance and results in faster lap times.

It must be said that many urethane bushes these days are available in varying degrees of hardness that can be customer specified. Apart from firmer connections, another big advantage of urethane is that it doesn’t perish like rubber. So, it should last much longer. Nathan says he still gets people through the shop who want a particular colour urethane because they think certain colours indicate degrees of stiffness. However, the only thing colour indicates is brand.

OUT OF JOINT

There’s always a mix of cars in the workshop at Advantage, and on the day we visited a Monaro and Torana were in for some work. The Torana is a full-on street car, and in the sensitive bush positions we discussed Nathan used Heim, or rose, joints (also known as rod ends). Heim joints are actually very compliant. That’s to say, they move very freely in the directions they’re supposed to, and in this application they allow the diff on the Torana to move quite freely without binding up.

That said, they have absolutely no longitudinal movement. This means they transmit a lot of NVH (Noise and Vehicle Harshness). In fact, OE suspension designers will tell you that longitudinal compliance in bushes is responsible for reducing a great deal of NVH. In large measure, that’s what Ford’s control blade suspension was all about when introduced. You need to be aware of this if you fit Heim joints. Still, you wouldn’t do it unless you were building an extreme street or track car and you knew what you were doing anyway.

SHOCK TREATMENT

Of course, shock absorbers and springs are vitally important components in the mix. Some people call shock absorbers dampers, but the fact is, neither term is acceptable. They certainly do dampen the action of springs but they also absorb the energy of disturbances in the surface of the road. They also get quite hot in doing so and then dissipate that heat to the atmosphere. Really, springs and shocks, or dampers, work together as a package. Call them what you will.

Some shock absorbers are described as gas shocks. While these containt they still contain oil. All shocks work in the same basic way. They consist of a tube full of oil that also contains a piston which can slide back and forth. The piston is attached to the end of the rod you see extending from the main body of the shock absorber. The reason the piston (and attached rod) can slide through the oil is because it has holes in it. Larger holes mean oil transfer through them is greater and the piston can move faster. Smaller holes increase resistance and slow the piston.

The holes in the piston are sealed by disc shaped shims that bend under oil pressure and uncover the holes so that the piston can move, or by valves that also control oil flow rate through the holes. The size and shape of the shims used varies and different types and sizes are stacked together on either side of a piston to control the damping characteristics. Adjustable valves also alter the flow characteristics to suit particular applications.

HOW LOW CAN YOU GO?

Shock absorbers can’t support a vehicle. Springs do that in addition to holding the vehicle at its designed ride height. Of course most suspension mods (from standard) involve lowering the vehicle somewhat. But Nathan said the myth that the lower and harder the suspension is, the better it will be, still persists. Nothing could be further from the truth. Some lowering is acceptable but going too far will generally upset the suspension geometry to the point that handling will be degraded.

Further, if the suspension system is so low that the springs compress and the system goes ‘solid’, the car will become an extremely heavy go-kart. The forces of braking and cornering will have to go somewhere and unfortunately that will be the bump stops, tyres and other uncontrollable areas of the suspension. The worst thing that can be done is to cut stock springs to lower a car.

In general terms, all classic cars will benefit enormously from upgrading the components we’ve mentioned here. It’s impossible to fit a model by model break-down of what each car needs into a magazine article. That’s what catalogues are for. But basically you’ll be fitting slightly lower springs that maintain a similar front/rear percentage difference in rate, shock absorbers with firmer valving, new bushes in both rubber and urethane, and uprated anti-roll bars.

As for what you’ll spend on a suspension upgrade, you can get a pretty good improvement for less than a thousand dollars or you can go really high end and spend many thousands. There really is something out there for just about everyone.

The Basics:

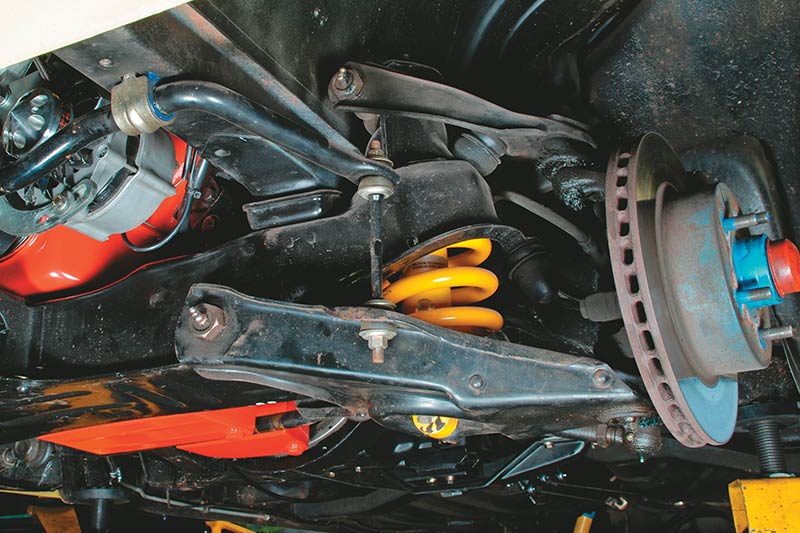

1. The Monaro swaybars are mounted in urethane but still connected by rubber.

2. New anti-roll bars are more than likely going to be needed on any car that’s a classic.

3. The rear of the Monaro front end. Note the bump stop. These are an important part of the suspension and should never be cut down.

4. Leaf springs can be fine when coupled with the right shock absorbers.

5. These new leaf springs from King come lowered. They are about the same rate as factory springs but shock absorber choice will adjust their performace. They are available for a number of cars.

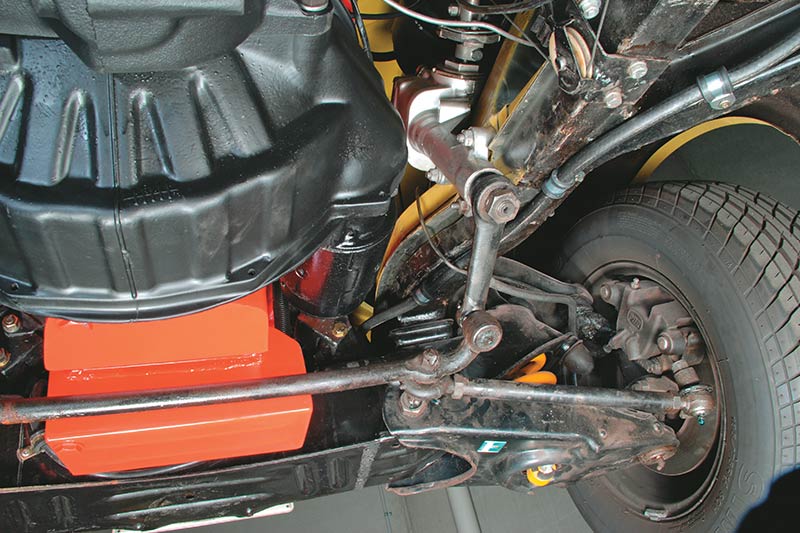

6. The Torana is more heavily modified than the Monaro.

7. Urethane is available for just about any purpose on a car. It can be ordered in different grades from some manufacturers.

8. Note the heavy duty mounting points on the Torana. This is built to deal with fairly serious street use.

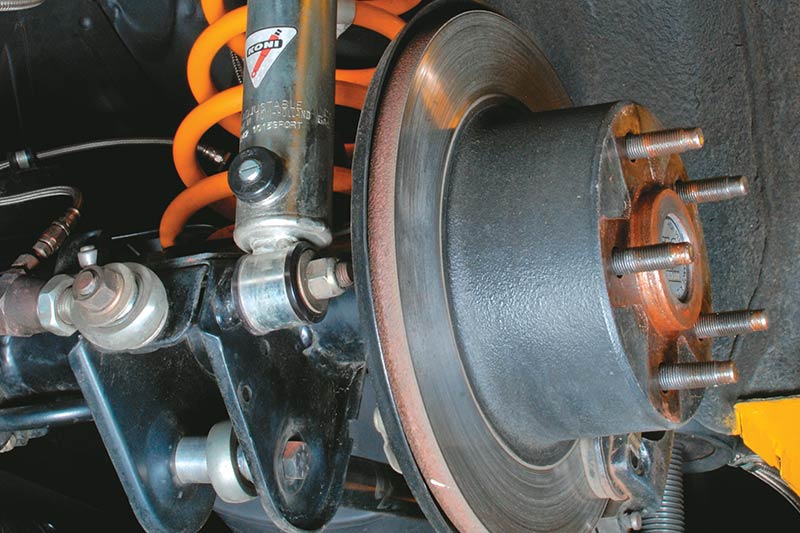

9. Despite the fact that the Torana rear is fully Heim jointed it’s still compliant in the dimensions that need it.

10. Double adjustable Koni shock absorbers control the rear King springs.

11. These are the bump adjusters on Koni and Bilstein shock absorbers. Rebound is adjusted at the top. Bump is when your suspension is being compressed. Rebound is when everything is expanding after the bump.

12. A Quadrant/Bilstein coil-over conversion for early series Falcons.

13. A piston and a couple of sample shims from a Bilstein shock absorber. The way these work is interesting; the subject of another article perhaps?

14. Toperformance/Koni have performance uprades for almost any car. Their customization database covers combinations for everything!

15. Fitting suspension components isn’t that difficult if you’re reasonably handy and careful.

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)