Workshop advice: Garage safety

Example of a bad setup with no supports

Example of a bad setup with no supports

Trolley jacks: Know the weight of your car

Trolley jacks: Know the weight of your car

Lubricating a hydraulic trolley jack

Lubricating a hydraulic trolley jack

Car stands

Car stands

Don't position jacks in concrete joins

Don't position jacks in concrete joins

Position car well with working space

Position car well with working space

Allow for movement

Allow for movement

Position the head cap on a centrally-located strong point

Position the head cap on a centrally-located strong point

Don't place anything between the head cap and lifting point

Don't place anything between the head cap and lifting point

Don't place jacks or stands on the pinch weld of a car

Don't place jacks or stands on the pinch weld of a car

Choose a strong, even part of the sub-frame

Choose a strong, even part of the sub-frame

Fully raised and ready for action

Fully raised and ready for action

Don't tug or rock a car suspended on stands

Don't tug or rock a car suspended on stands

Use a breaker bar so the force is applied directly downward

Use a breaker bar so the force is applied directly downward

Use an impact wrench or ball joint separators to reduce tugging

Use an impact wrench or ball joint separators to reduce tugging

Ramps must be on hard and even ground

Ramps must be on hard and even ground

|

|

Example of a bad setup with no supports

|

|

|

Trolley jacks: Know the weight of your car

|

|

|

Lubricating a hydraulic trolley jack

|

|

|

Car stands

|

|

|

Don't position jacks in concrete joins

|

|

|

Position car well with working space

|

|

|

Allow for movement

|

|

|

Position the head cap on a centrally-located strong point

|

|

|

Don't place anything between the head cap and lifting point

|

|

|

Don't place jacks or stands on the pinch weld of a car

|

|

|

Choose a strong, even part of the sub-frame

|

|

|

Fully raised and ready for action

|

|

|

Don't tug or rock a car suspended on stands

|

|

|

Use a breaker bar so the force is applied directly downward

|

|

|

Use an impact wrench or ball joint separators to reduce tugging

|

|

|

Ramps must be on hard and even ground

|

DIY maintenance expert, Paul Tuzson, takes us through how to work safely under your car

|

|

Workshop: Garage safety

|

GARAGE SAFETY

Often, we show technical stories that involve working underneath cars. We seek out experts to show how to do the things we’re describing but the problem is that experts all tend to have hoists, while readers generally do not. So, to do some of the work we dsicuss an average reader needs to get a car up onto support stands. This is an inherently dangerous thing to do and people are killed or injured pretty regularly when the process goes wrong.

The number one way to avoid injury in these circumstances is to completely avoid getting under a car while it’s supported by a jack only. While everyone surely knows that, it’s amazing to note who takes adequate safety precautions when working under a car, and who doesn’t. The most dangerous attitude you can have is to think ‘It’ll only take a minute or two, I’ll just be quick’. Quick you may be but accidents only take seconds, or less! Amazingly, I’ve seen qualified mechanics work this way.

Most of these accidents are preventable if suitable equipment is used properly, however there’s always risk involved in crawling under a suspended car and wrestling with it. In general, it’s a process best avoided although sometimes that’s not possible. Besides, most of us like working on our cars. Therefore, if you are intent on crawling into the narrow space between your car and the ground the following information can serve as a general guide for doing so safely.

WHAT YOU WILL NEED

Tools:

- A very flat and even area of fairly smooth concrete.

- An Australian Standard compliant trolley jack.

- Four Australian Standard compliant support stands.

- One or two purpose-made wheel chocks.

- An assistant, preferably with a second jack.

Cost:

A decent but relatively limited trolley jack can be found for as little as one hundred and fifty dollars. It will lift one end of a car but won’t have the service life of a trade quality jack. A smaller workshop quality unit can be had for around four hundred and fifty dollars upwards.

A pair of heavy-duty support stands can be had for around fifty to seventy dollars or upwards depending on adjustability. It’s worth checking the websites of typical consumer auto stores for specials. Sometimes they have amazing offers. Time:

Getting your car up on four support stands may take up to fifteen minutes if you have to do it in stages. Really, you should take your time. If it falls on you because you rushed you’ll have to add the time taken for the ambulance ride. It could be a life time.

1) MEET YOUR STANDARDS

You should know the total weight of your car and ensure that your hydraulic trolley jack can support more than three quarters of it. The jack should be compliant with Australian Standard AS/NZS 2615:2004 and have a label that says so affixed to it. Each pair of support stands should be capable of supporting the whole weight of the car. Support stands should comply with Australian Standard AS/NZS 2538:2004 and again, should have labels indicating that this is so.

The blue workshop jack in the centre is well designed and will fit under most lowered cars. The inexpensive consumer-grade unit to the right is higher in lowered state. This and the grey stands were on special when we were researching the story and the prices were so good we simply bought them. The jack was half price at just seventy dollars. The screw adjustable stands were seventy dollars, which is about normal but the black pin-only units were on special for just under twenty dollars. The stands are very heavy duty and each one will support three tonnes. So together the four can support twelve tonnes, which is more than enough for most cars.

2) LUBE IT

Trolley jacks must be able to roll and operate freely so ensure that all moving points are lubricated. It’s not a bad idea to get into the habit of doing this every time you use a jack.

3) STRONG IS GOOD

The more heavily constructed stand on the right is generally a better design than the lighter one on the left. It’s double pinned and each half of the pin is thicker than the single pin in the lighter unit.

4) THE CAVERN OF DEATH

This is an excellent example a bad setup. First and most obviously there are no support stands under the car. Also it’s very close to the drums and wall which would make it harder to get out from under the car if things went wrong. There’s also another car parked very close to the right, just out of the photograph.

5) THAT'S BETTER

The car is positioned well here with good working space all the way around. The concrete surface on which you plan to jack and support the car is important. It should be smooth enough to allow the jack to roll freely as it takes the weight of the car. Overall it should also be level enough to prevent the car from rolling without the handbrake or wheel chocks applied. Never try to jack or support your car on soft ground or thin concrete. It should be at least 100mm thick. If you’re not sure you can drill hole through it in an unobtrusive corner with a masonry bit and measure the depth with a bit of wire.

6) STAY OFF CRACK

this is a bad position for a jack. With the wheels sitting in the concrete join the jack won’t be able to roll freely when the weight of the car is on it. Avoid joins in the concrete under both the jack and support stands. A word about other types of jacks is in order. Some classics like Fords were supplied with jacks designed to attach to bumper bars. These are only designed to lift one corner of a car to change a wheel. Even then, they tended to bend the bar mounting brackets and this is sometimes evident on cars of that era. Using one to lift the whole half of a car is quite likely to bend the mounts.

Similarly, compact threaded scissor lifts should only be used in the positions specified by the car manufacturer and only to lift one corner at a time to change a wheel. They should never be used to lift the whole end of a car to get it onto stands. It’s also worth remembering that wheel-changing jacks are only designed for limited use. They’ll wear out much more quickly than workshop jacks and failure in this sort of jack can be very sudden and complete.

7) SPOT ON

Pretty obviously, a centrally-located strong point is the ideal place to position the head cap (that’s what it’s called in the Australian Standard) of the jack. On this HT Holden the middle of the cross-member shown is the perfect spot. People have been known to use the oil sump but that’s a very bad idea. Also, the head cap should never be placed under any steering or suspension components like tie-rods, control arms, radius rods, steering connector rods, anti-roll bars, or, basically anything that moves in any way in relation to the chassis/body.

8) KEEP A CLEAR HEAD

Basically, there shouldn’t be anything between the head cap and the lifting point. Some jacks are fitted with rubber cushion pads to improve grip and avoid damage to paint but most aren’t. If you’re concerned about this you can fold over a couple of layers of rag to protect the paint but that’s all. It’s common practice to set a block of wood on the head cap but that’s actually a bad idea for a number of reasons. In any case, it contravenes the standards which say that anything added to the cap shouldn’t increase its lift height.

9) ALLOW FOR MOVEMENT

As a trolley jack is raised under the front of a car, the head cap moves backwards through its arc of travel toward the handle perhaps five inches or more. To accommodate this movement the jack will roll toward the rear of the car. But if the wheels of the jack become jammed the jack will pull the car forward further over the jack. If both the car and the jack are prevented from moving the head cap will be dragged to a different contact position, which could well end in disaster.

Chocking the wheels of the car ensures that the movement described will be converted to longitudinal displacement of the jack. This has the benefit of allowing the car to be lowered onto the support stands a little more accurately. Chocking the wheels of a car being jacked up and placed on stands shouldn’t be considered as a means of preventing the car from rolling in general. As we said earlier, the area chosen for this task should be perfectly flat; there shouldn’t be any danger of the car rolling away. If there is, don’t try to set the car on stands at that location.

It’s a good idea to get the stands positioned under the car as soon as they’ll fit at a low setting. When the car is as high as it will go they can be fully extended and the car lowered onto them.

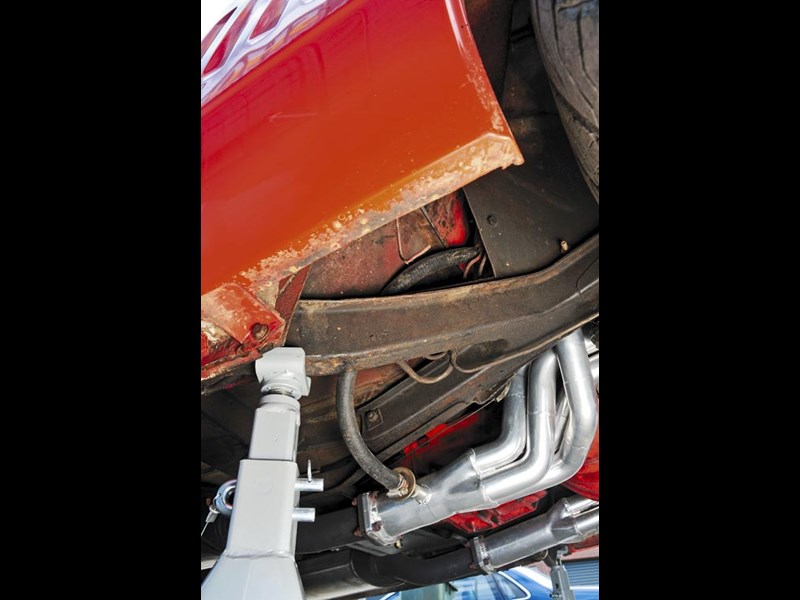

10: IN A PINCH

Jacks and support stands shouldn’t be placed under the pinch weld on a car of this age because it will simply bend. A strong section of the sub-frame or similarly strong location in another car is the best place. In the HT Holden shown, this section of the sub-frame isn’t bad but care is needed in placing the stand because of the upward slope of the frame. If the stand were placed on the sloped section it would be unstable. Note how the stand has been placed in relation to the join in the concrete.

11) DIFF DUTY

Down at the back of a classic car like this things are easy. The centre of the differential housing is about the best place to position a jack and the axle tubes are actually the support points for which support stands are designed. In fact, AS/NZS 2538:2004 says that the engagement head of an axle stand should be capable of supporting a 100mm diameter tube even if the stand is tilted up to five degrees from the vertical. If you want to remove the axle you’d probably place the stands at the front hangers of the rear springs or a similar hard point capable of supporting the car’s weight.

12) STEADY AS SHE GOES

Here you go. It’s fully raised and ready for action. Jody is a pretty strong guy so we got him to give the car a bit of a shake to ensure that it was firmly set on the stands. You don’t want to push it sideways off the stands (it’s worth keeping in mind that you could) but you do want to make sure it’s firmly mounted. Having two stands with thread adjustable engagement heads ensures you’ll be able to.

13) DON'T TUG

Getting a breaker bar onto a stuck bolt and cyclically pulling sideways to get it undone is one of the worst things you can do under a car suspended on stands. This can set up a rocking motion capable of rocking a car off the stands.

14) BREAKING GOOD

It’s better to use a breaker bar so that the force applied is directly downward, towards the ground. Even though the stands are in place we like to leave the jack locked in place as an extra safety measure. As we’ve said, though, don’t get under the car when the jack is the only thing supporting it.

15) MAKE AN IMPACT

The very best way to get things undone under a car on stands is to use an impact wrench. These apply tremendous torque and don’t set up a sideways tugging motion. They’re fast, too. You want to spend as little time as possible under there. Also, if you’re pulling out heavy items like transmissions, have a helper and use a support stand designed for the job. Randall (shown) says he was once pulling a transmission out and it completely pinned him. If he’d been alone he says he’d still be there. A creeper trolley will make things easier under a car and also allow you to get out from underneath more quickly if needs be. However, as you can see, even at full height there still isn’t all that much space under a raised vehicle. Other tools that reduce tugging, like ball joint separators, are also a good idea.

16) RAMP IT UP

Ramps can be a quick way to get a car up but they must be used on hard and even ground. Some are very lightly constructed with the minimum of welds. Note that this one had been used on soft ground resulting in the twist distortion shown in the lower rail. Getting a car back down off support stands is pretty much the reverse of what we’ve described here except for the precautions. They’re the same. Don’t get under the car at any stage during lowering when the stands have been removed. If you’ve forgotten something, set the car back on stands before you go under to deal with it. It’s the best way of staying alive.

TOP TIPS

Probably the top tip when you’re going to attempt any work whatsoever on your car is to make sure you have an owner’s manual.

Never get underneath your car while it’s supported only by a jack. Make sure it’s properly supported by support stands.

Purchase support stands that are capable of supporting much more than the full weight of your car.

Keep your jack clean and well lubricated and ensure that it meets Australian Standard AS/NZS 2615:2004.

When it’s time to finally get under the car and do some work try to use a creeper trolley to make things easier and safer.

KNOW YOUR CAR AND EQUIPMENT

If your owner's manual shows specific lift points use them to lift and support the car if that’s possible. However, that’s not always possible.

If you haven’t lifted a particular car before figure it out in advance. With the car at rest on the ground measure the distance between the lift point you plan to use and the ground.

Raise your jack to maximum lift with nothing on it and measure the extended height. Subtract the ground clearance figure obtained in the previous step. The result is how far your jack will lift your car.

Measure the ground clearance at the point where you plan to position the axle stand. Raise one of your support stands to maximum extended height, measure it and subtract the ground clearance.

Make sure that your jack can lift your car high enough to get the fully extended axle stand into position underneath your chosen support point.

You may be surprised how little space there is under a car on support stands. Work out if there will be enough space to do the job you have in mind.

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)