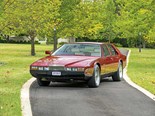

Aston Martin DB2: Reader Resto

.jpg)

.jpg)

.jpg)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Australia's Le Mans Champ, Vern Schuppan, turned to Gerard Miller from Marque Restorations for an Aston Martin DB2 resto that snagged the 2014 Motorclassica top brass. Here's how it was done.

|

|

Vern Schuppan’s Aston Martin DB2

|

Aston Martin DB2 resto

It’s not often you get to restore the car of a Le Mans winner. They tend to be pretty exacting in their demands, so it was with both excitement and trepidation that I took on the restoration of Vern Schuppan’s Aston Martin DB2. I didn’t regret it though. It was a gorgeous car which came out looking like a million dollars. When he came to me again about two years ago with another one, and said it needed to be better than his last car, I knew we were embarking on a very special journey.

Co-owners Mal Hemmering and Vern sourced the DB2 from the UK, previously owned by an Irishman in Belfast who bought it new and raced it in competition a lot. He was actually the Aston Martin Owner’s Club representative in Ireland who’d had the engine rebuilt in about 1968 and didn’t drive it a great deal afterward. The chassis had been knocked around and started rusting, he didn’t get it fixed and the car sat around a long time until Vern and Mal came into the picture.

When the Aston got to me, the first thing we did was take the body off, dismantling it piece by piece, right down to the bare chassis with just the drivetrain. Vern took it for a quick lap around the block and came back with a big smile on his face, probably because the engine hadn’t done many miles since that 1968 factory engine work. It still runs like a Swiss watch.

We did everything to it, bar the inside of the engine. We did the gearbox, the diff, the steering box, water pump, suspension – which was quite tricky. It’s got a Healey-style front end; in fact I wouldn’t be surprised if it was drawn up by the same guy.

Obviously somebody had worked in the aircraft industry because there are lots of fancy castings with nuts and bolts that are very aerospace in their design – it’s such a beautiful piece of work to see. But that makes it complex. The anti-roll bar goes through a cast aluminium suspension mount, made of six pieces bolted together. These components were worn hard from racing. We salvaged as many bits as we could; some of them had to be sourced from the UK; a few were remade. Caster and camber angles are adjustable for racing, and some of the early cars that went to the States got bad write-ups for poor handling, but when they made these racing tweaks they were much nicer to drive. We did the factory mod to the caster and camber on the king pins and spindles. For the live rear axle we replaced twin trailing arms with cast aluminium links at each end and coil suspension – coils were quite unusual at the time, quite sophisticated. The chassis is made of rectangular and square tube, brilliantly designed. Without any body on it it’s a gorgeous engineering work. So many classic cars have remnants of previous models or share designs and patterns – they’re compromised, but with this car everything was purpose made and it was a rare opportunity to appreciate that. Everything was thought through; nothing was rushed in its design – it’s a work of art.

The engine is a beauty. A twin overhead cam six-cylinder from Lagonda after David Brown bought the company, originally designed by W.O. Bentley. Another wonderful piece of engineering I have a lot of time for these motors. Every bit on the outside of the motor we did. We had the manifolds off, the sump off; rebuilt everything we could in that regard – carburettors, shafts, butterflies, distributor – every bit needed a lot of work because in ’68 it only went to Aston as a bare motor. I’m sure they’ve put in a new crank, new rods, new pistons. We had to rebuild the differential too, and being low production, at every stage nearly, the sourcing of parts is what takes time researching and ordering.

The gearbox is a David Brown four-speed synchromesh gearbox, what he was famous for. The body is light tube frame with thin aluminium skin over the top which makes it really light and quite strong. It’s the Superleggera design that body company Touring were famous for, which Aston Martin got involved with. I’ve worked on Lancias and Astons from the same era, all done with Touring, and the Aston cars are superior in the quality of fabrication – they’re exquisite. The aluminium welding is perfect, they built them like they built aircraft.

We cut a lot of aluminium out of the DB2 and unpicked the skin, sandblasted the frame, welded in new steel, made up new A- and B-pillars which were originally made from wood, made new sills, doors, quarters, inner guards, metal finished the body, put the skin back on the primed frame, made new hinges for the bonnet. We also had every single little piece of chrome work re-done, all of which was damaged, and Vern and Mal wanted it absolutely perfect. We had to make every single grille bar faultless – all stripped and re-chromed individually. The brass headlight ring bezels had to be stripped, tapped out smooth and re-chromed.

We made a whole new floor, exactly as the old one was, using aircraft-style rivets countersunk like the originals. There were a few hundred root nuts in there that had to be made to replicate the original. Lots of aluminium castings had to be made for the suspension; the aluminium spring hangers weren’t much chop and often failed on these cars so we had to find them from the UK. Tim Stamper is the guru for finding these parts in the UK for DB2s – he does a lot of racing and work on these cars and was very helpful.

The battery case is an old Lucas replicated piece, which we even stamped with a part number. On the fanbelts, we had some masks made so we could stamp ‘David Brown’ on the outside of the belt.

Allan Smith Motor Trimming is my go-to place for interiors and has been for about 23 years. Allan is brilliant, and we work well together – teamwork is crucial for this kind of restoration because Vern and Mal weren’t going to settle for average.

With improving the safety of the DB2 becoming part of the project’s blueprint you have to think two steps ahead to disguise the modifications to avoid affecting the original car. A key modification was building a collapsible steering column into the old car’s original parts. Even my father was a key player in helping us do that using his skills and even if you went looking for it now, you’d never know it was there. It’s hard to just make it work, let alone to get it seamless. But the most challenging part was that bodywork. Doing it and doing it so perfectly that it doesn’t even look like it’s been touched, then getting all those tiny details, the pins, the clips, the washers, the gaps, the threads and the lengths of the threads on period style bolts, to the same standard – that’s the hardest part. It takes serious patience, but ultimately that’s what finishes the car perfectly and gives you pure satisfaction.

I knew both Mal and Vern’s expectations were very high with this car – they didn’t have to tell me. In the last week or so as it neared completion, we literally had everybody in the shop working on getting it finished and on the trailer. I had the pleasure of driving it through the zoo and into Motorclassica at the Exhibition building. To come home with ‘Best in Show’ and ‘Restoration of the Year’ was awesome. We had a big celebration when we got back the following week because I think it’s definitely one of the best cars I’ve been fortunate enough to work on.

INSIDE STORY

Allan Smith says working with Gerard Miller on Vern and Mal’s DB2 was as enjoyable as it was difficult. "The hardest part was finding Connolly leather in suede green. I secured the last two new-old-stock hides and a third replica hide from specialists Leffer H. & Son in South Melbourne. The NOS hides are full grain leather with the Connolly stamp, which is no longer made.

"The carpet is Heritage English Wool, a broad, heavy 32oz wool, so very hard to find, especially in the correct colour."

Allan’s workshop, bristling with specialist talent, also re-made and bound the door cards and dashboard in leather, as well as working closely with Marque Restorations to restore the car’s original wood pieces.

"The timber trims were originally covered in leather, which helped preserve the wood somewhat, but it was still swollen and faded. Marque would make prototype timber for the

first fitting, then I would finish it off with treatment, gloss and then leather trim."

"The dash was ‘very handmade’, as I say. It had to fit as a bespoke piece because the car is not symmetrical from the left to right-hand side. The seats were actually near enough to perfect, with the latex foam protected from UV damage by the leather. Marque straightened and re-chromed the frames, and we made up new leather covers."

"This was my first DB2, which was fiddly and needed some finesse, but experience on later Astons and plenty of E-Types helped with the learning curve. It was a pleasure to work on Vern and Mal’s Aston as a team and I’m very glad I was able to contribute to such a gorgeous car."

LEGACY OF A LEGEND

Vern Schuppan, who became the first Australian Le Mans winner in 1983, has made this DB2 restoration very special with his own expertise and flavour. With good friend Mal Hemmering, also a bona fide car nut, they worked closely in finding the Aston in the UK, bringing it Down Under, and planning the car’s journey carefully with Gerard Miller at Marque Restorations in South Australia.

"I used to store my old DB2 at Mal’s place and he fell in love with it. He hopped in it and was very smitten. So he came to me when he decided to start looking for one of his own. My old DB2, which I’d also had restored by Gerard at Marque Restorations, was chassis #16, making it more of a prototype. Mal’s car, which is a later build, was known as the "three grille" DB2, and these were the more desirable and many have changed their cars to look like the later models.

"The original cars had timber frames and would scuttle quite badly, but Gerard’s fixed that issue, it’s a much stiffer and better car to drive. It’s also safer as a result, plus the collapsible steering column, side intrusion bars made from chrome moly tubing – all things we’d talk about and agree on. It was fun to be involved from the get-go because we all had the same goal in mind.

"Gerard knew that the premise was to restore original parts, replace them with original parts, or re-make them. I didn’t have to dictate or deliver instructions; we just consulted and everything gelled.

"To me the DB2 has such a great art deco style which I love. I wouldn’t say I’m an Aston or even a DB2 tragic, I just love that 1950s shape – MGs, Astons, Ferraris – all timelessly shaped. Back when I was at school all the kids would see these cars and just think, "Wow! Imagine having something like that." Then you get one and they don’t quite match the fond memory. But then again you think about their design, for the 1950s, and you appreciate them in a whole new way."

With cars from this era, Vern reflects on his decades of classic car restoration experience. "You have to be patient when restoring them," he says. "My trade is paint and panels, and Gerard’s got the same background – you actually had to fix something because there weren’t replacement parts readily available. You metal fill, you cut, sand, buff and paint everything yourself. That’s where the enjoyment is because you put in absolutely everything you have – mentally, physically and financially – and you can stand back at the end and be proud of yourself."

Vern says despite the enormous input he never saw Gerard’s team defeated or despondent. "Everyone there has a great work ethic. In fact it took twice as long to finish as we’d planned, but that’s the nature of these cars; you don’t just bolt them back together. You’re giving them new life and that can’t be rushed."

Of all the cars Vern owns, and his list is impressive, he drives the DB2 the most. Don’t blame you, Vern.

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)