Project GTS: Pump it up

|

|

|

|

|

|

|

|

|

|

|

|

What's the best fix for your Holden bent eight? Pump it up to 355 cubes, of course

Project HQ GTS tribute

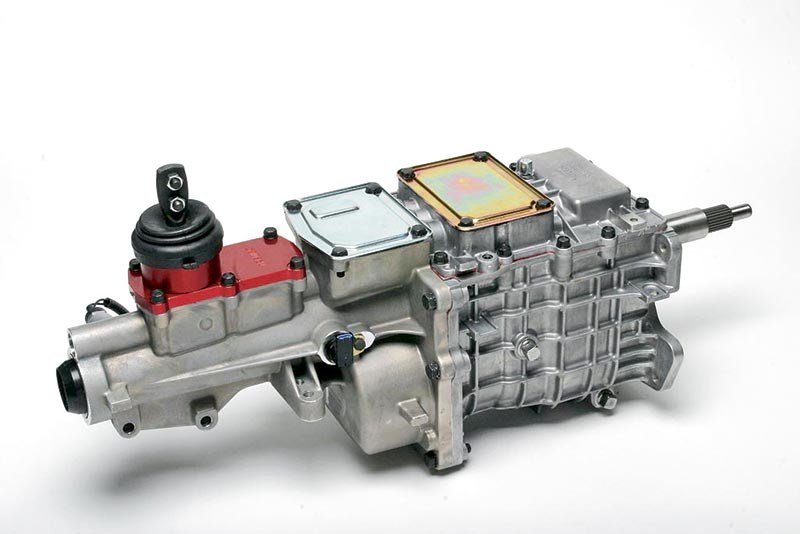

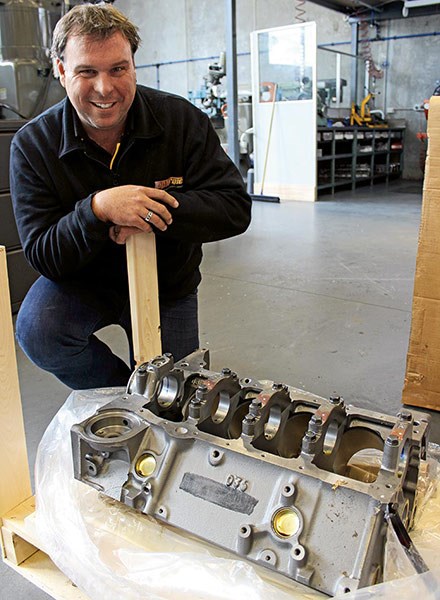

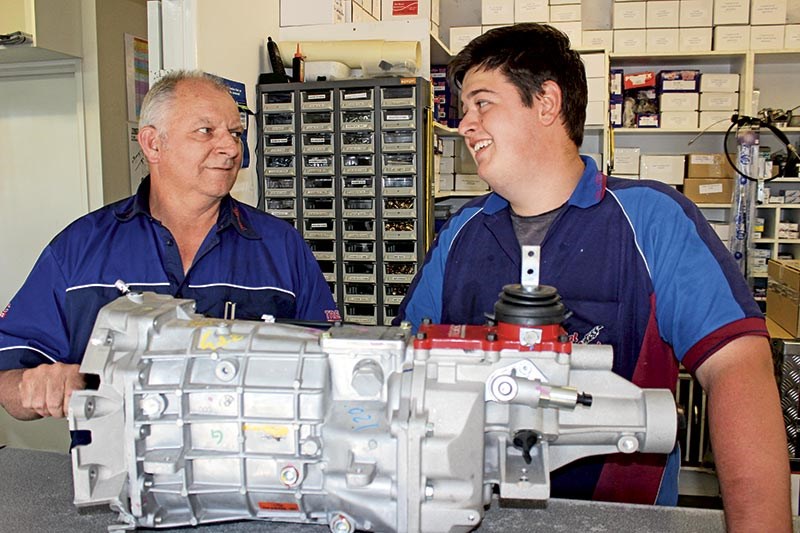

Just as our Project HQ, being built by the clever folk at Bendigo Retro Muscle Cars, is about to hit the road, we thought it was time to reveal a little more about the mechanicals. Last time we had a good look at what was going under the bonnet, the engine block – a late model 304 unit - was being decked before the serious work of relieving it to take the stroked 355 cubic inch set-up we had in mind.

Why a 355? Sean Griffioen of Top Torque in Melbourne was leading the rebuild – one of several the firm has now done for us. His response was simple: "They are a good package amongst the boys on the street. Once you’ve driven a 355 compared to a 308, there’s no going back. It’s a really good torquey engine and really lively on the street. In an early Commodore, or HQ or Kingswood, they’re nice and light and make a really good little package."

Fair enough, so what’s the story with altering the block for the bigger capacity? "The biggest challenge is getting the rotating assembly to turn. The extra stroke causes the conrods to hit on the opposing bore – that’s probably the biggest hurdle, making sure you’ve got adequate clearance once it’s in the block.

Precision International supplied the internals for the powerplant – again, they’ve now been on board for several Unique Cars mag projects and, like Top Torque, do a brilliant job. They supplied a Scat 3.48in nodular iron crank, mated to 5.7in I-beam Chev-pattern rods on King XP bearings. They included a stud girdle to brace the block, something developed with American firm Philadelphia Racing Products.

"From there on you do your boring and honing and all your regular machining," explains Sean, "And you start your assembly process. So you need to make sure your compression ratio is adequate.

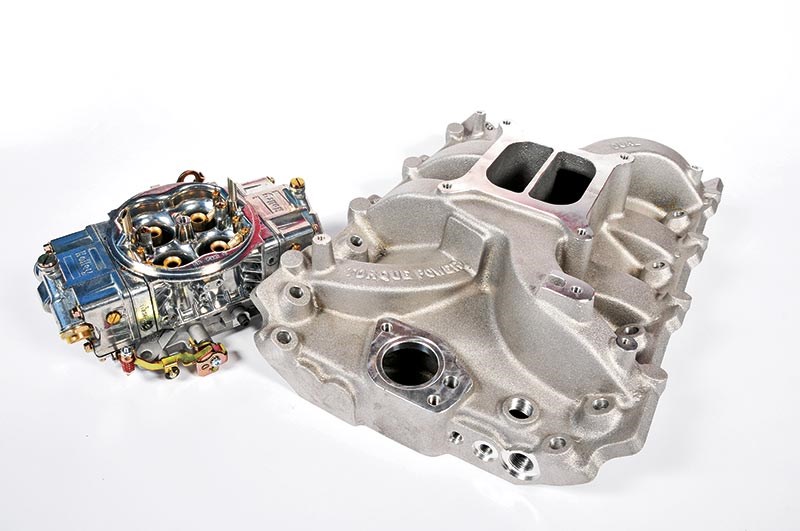

Sean is a fan of not going over the top with cam choices: "Good camshaft selection is always a must with the 355. People can get carried away and go too large in the camshaft and that doesn’t get the desired result."

He also warns against going mad with the carburettor – another temptation. "People lose sight of the fact it’s only 355 cubic inches. Although it’s a massive gain over 308 cubic inches, you think of it as a standard 350 Chev. Get some proper advice to make sure the job is right once it’s in the car."

Read the full story in issue #375 of Unique Cars, out now.

|

Unique CarsIssue #375On sale now |

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)