Bolts and bush fixes - Mick's Workshop 453

|

Woodturning for the mechanic, and Mustang mayhem

Okay, I thought this time around I’d revisit one of my pet hates, which is seeing a carefully rebuilt engine held together with old and sad looking bolts. To me, it’s a huge wasted opportunity to make a real visual impact with very little extra

expense and trouble. Particularly these days, when there are hordes of suppliers out there offering alternatives.

Now the more experienced among you may well be aware there are many different types and styles of fasteners out there, including the usual metric, SAE, Whitworth and so-on. The world was meant to go completely metric 30 or more years ago, but it never really happened. What we got was what they call a soft conversion – some areas ‘took’, others didn’t.

You can still get tools and components for all those types of bolts (though Whitworth has got tougher over the years), and you may need specialist advice, as this will often be beyond your corner auto store. A dedicated tool shop and/or bolt shop is often the go.

You might have heard it before, but the right tool makes all the difference. So, use a metric spanner on a metric head, or an imperial/SAE on that sort of bolt. Mixing and matching never really works, particularly when there’s a bit of force required. Use the wrong one and you end up with rounded bolts and skinned knuckles.

Speaking of rounded bolts, I’m a fan of some socket kits sold by Wurth, which have a spiral-machined inner and are designed specifically for removing nuts or bolts with damaged heads.

The maker describes them as twist sockets and they are incredibly tenacious. In fact, the kit is supplied with a little punch to remove the offending item from the socket, once you have it off. They’re not cheap – I recall around $250 for a set of 14, but I reckon it pays for itself the first time you use it.

When it comes to doing up an engine, I like to do a few things. For a start it pays to take the trouble to clean out the threads, so any new bolt isn’t picking up swarf or debris that does damage. Secondly, I like to send off the original bolts (if they’re still okay) to be cleaned and nickel-plated. They’re often kept as a stand-by. Sometimes there might be just one case where you have to have the original.

I’ll also order in a fresh set of stainless bolts, particularly for areas that are on show. It’s only a little thing, but makes a huge difference to the overall finish. You can get sets for a lot of engines and they don’t necessarily cost a fortune. It’s money well-invested.

Here's my tip:

Love me tender

We keep hearing reports of people having disasters with battery tenders, varying from meltdowns of the battery itself, though to fires. A couple of quick tips. First, if you value your shed, buy a quality unit. Second, I’m not a fan of having them going 24/7 – put them on a timer. An hour or two a day will suit most purposes. Last, make sure you’re using the correct charger for the type of battery.

LETTERS:

Ghia Keeper?

Nice car to get around in, but not really on the collector radar

I recently bought a 1999 Fairlane Ghia with six-cylinder Tickford engine (running on lpg or petrol) for $3000. The body is very straight and the interior is in good condition, all the electrics work and it has full service record since new. Mechanically it is in good condition even though it has done 270,000kms.

The left rear door however will not open either from the inside or outside suggesting the door catch is broken or disconnected. Do you have any tips for removing the inside door panel? The main problem I have is getting access to the clips at the bottom.

Although this car was bought as a cheap run around car (I have two classic cars under cover) I am wondering if there is any indication that this model will become collectable and increase in value in the next few years?

I enjoy your column with its down-to-earth advice.

Garry Wilson

IT’S POSSIBLE you have two problems with the door – one being the outer catch is broken and the second being the child lock for the inner is stuck on.

In any case those trims are a bit of a bugger to remove and require lots of patience. Believe it or not, sometimes pulling out the lower rear seat will help by giving you more elbow room.

You work from the lower edge and might have to accept you will break clips along the way. You should be able to find replacements.

I don’t see that model becoming collectible, so it’s a case if you like hang on to it. Good luck with it.

Coughing XR

Hi, we’ve got a bit of a problem with a 289 XR Falcon V8 that we’ve just put back together. Aside from a mild cam, it’s fairly standard with a 650 Holley and an electronic ignition.

It fires up okay, but won’t keep running smoothly. It is instead coughing and spluttering. It’s getting fuel and air, the carburettor settings seem about right, and there seems to be spark. Any thoughts?

Dave Carlson

THAT SOUNDS like a similar issue to a Mustang we’ve had in recently. All nicely set-up, but sounding like it had the flu. We tracked the problem to the electronic ignition conversion, which was kind of half-baked. The distributor now had an electronic trigger fitted, but the old wiring and coil were still in place to look original, so the voltage was incorrect.

When you do a conversion, you need to go end-to-end on the ignition, making sure everything is matched and getting what it needs – something we emphasised in a recent story with Performance Ignition Services. I’m pretty sure that’s where you’ll find your problem. Let us know how you get on.

Mechanical Carpentry

In relation to Rob Blackburn’s story about the A-model Ford with the timber piston: When I attended Gymea Tech College, in the early 1960s, as part of my mechanic’s apprenticeship the resident teacher, a Mr John Dare, related this story to the class. When the question of the type of timber used was raised, we were assured that Gidgee wood (the third hardest wood in the world) was the chosen timber.

The story goes on to say that when the cylinder head was removed when a replacement piston had been procured it was discovered that the timber piston was in such condition that the decision was made not to replace the gidgee wood piston at that time.

Gidgee wood is so dense it weighs 1300kg per cubic metre Mick’s workshop tip using pine-o-cleen to clean the cooling system is one I had not heard of. I thought as a motor mechanic for sixty years, 1961 until 2020, I had heard all the tips and tricks in the industry but you find you are never too old to learn something new!

I have used washing soda with great success to clean cooling systems, just break it up so that it will go into the neck of the radiator, put a good handful in, top up with water and run the engine for a while or drive for 10 or 15 kilometres then pull the lower hose off from the radiator so it drains quickly, if necessary repeat the procedure I look forward to the magazine arriving each month

Carl Dahl-Helm

Darwin NT

I LOVE the specifics in the wooden piston story, Carl, such as the density of the wood. Nevertheless, I’m afraid not a believer. I suspect that, density or not, it’s going to get toasted. We looked it up and apparently Gidgee wood is much-favoured by the barbecue and meat-smoking set, as it burns very hot for a long period of time. That’s not so good in an engine.

I can well believe washing soda would work as a flush in cooling systems, though you’d want to be sure that we’re talking iron and steel systems only. As you probably know, washing soda (or sodium carbonate) has a tendency to strip aluminium.

That’s why I like the Pine-o-Cleen option, as it seems benign. Remember it has to be the ‘brown’ version – don’t ask me why!

More Mechanical Carpentry

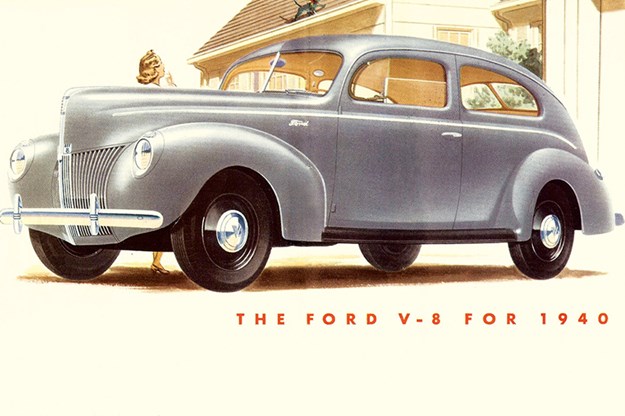

You would have been king of the street with one of these back in 1940

I can relate to Rob Blackbourn’s past experiences with Henry Ford’s transverse leaf spring suspension; In Rob’s case relative to a 1934 model V8. (Last issue, Rob related a story of having to do a dodgy roadside repair, which replaced the missing leaf springs out of the front of his old Ford with a length of Eucalypt – Ed.)

My late father owned a 1940 ‘Deluxe’ V8, back in the 1950s with the identical radius rod and spring set up. Ford US stayed with that design on their cars till the more modern 1949 model was introduced.

Issues my Dad had with the front spring assembly related entirely to the state of the dirt roads servicing the numerous sawmill settlements on the Eastern Dorrigo. From where we lived it was just over 50km to the nearest major town, which was Coffs Harbour, and that was a 75 minute trip.

Corrugations and potholes were standard fair plus a good smattering of dust. After numerous failures of the main leaf in the front spring assembly, my old man used the sawmill workshop to modify an extra leaf to fit immediately under the existing main leaf. A couple of guide brackets were added for location security, but after that was installed the front end worries were gone forever.

Eric Waples

I LIKE THE idea of the extra spring leaf. One of its effects would have been to slow down the oscillation of the assembly over corrugations and I can easily believe it would have worked a treat.

Floored Batteries

Have read with interest the discussions on battery life and discharging when placed on concrete floors.

Back in the day, while working at a boarding school in Fiji, I had the task of installing a large generating set in the plant room. It came with two large 12 volt batteries. They sat on the concrete floor for nearly two and a half months while we did the rather difficult installation.

Once ready, we connected the batteries and hit the starter button. The big diesel roared into life.

I recently had a good run with car battery – nine and half years in a Toyota Echo that had 320,000km on it before I disposed of it.

Fred Cracknell

AH, THE old battery debate – do they go dead faster if left on a concrete floor? I’m not convinced this was ever solved to anyone’s complete satisfaction. However I suspect the temperture of the floor rather than the material might be more significant, given lead-acid batteries in particular aren’t fond of the cold. In any case that’s a respectable life out of the Echo. Well done.

TRIVIAL PURSUIT

Electric pope

Though details are scant, The Pope Manufacturing Company in the USA (which tried its hand at most things) is credited with conducting the first media launch of a car. This was in 1897, for an electric vehicle. In a less than auspicious start for the electric vehicle industry, they built 500 in two years before selling off the design.

Want some advice on a build or a potential car purchase. Heck we’ll even tackle long distance diagnosis.

Drop Mick a line at uniquecars@primecreative.com.au

From Unique Cars #453, May 2021

Unique Cars magazine Value Guides

Sell your car for free right here

Get your monthly fix of news, reviews and stories on the greatest cars and minds in the automotive world.

Subscribe

.jpg)

.jpg)

.jpg)